ニュース&イノベーション

Temperature plays a crucial part of the wash process. If appropriate temperatures are not reached, it could result in dirty or stained linen, or worse: improperly disinfected linen. With a current emphasis on safety and reduced contamination, it is no understatement to stress the importance of guaranteeing the correct temperatures throughout your wash cycle.

Temperature on the wash process

Increasing temperature increases the energy and movement of molecules in the wash process. This helps your wash process in several ways:

Temperature’s role in disinfection

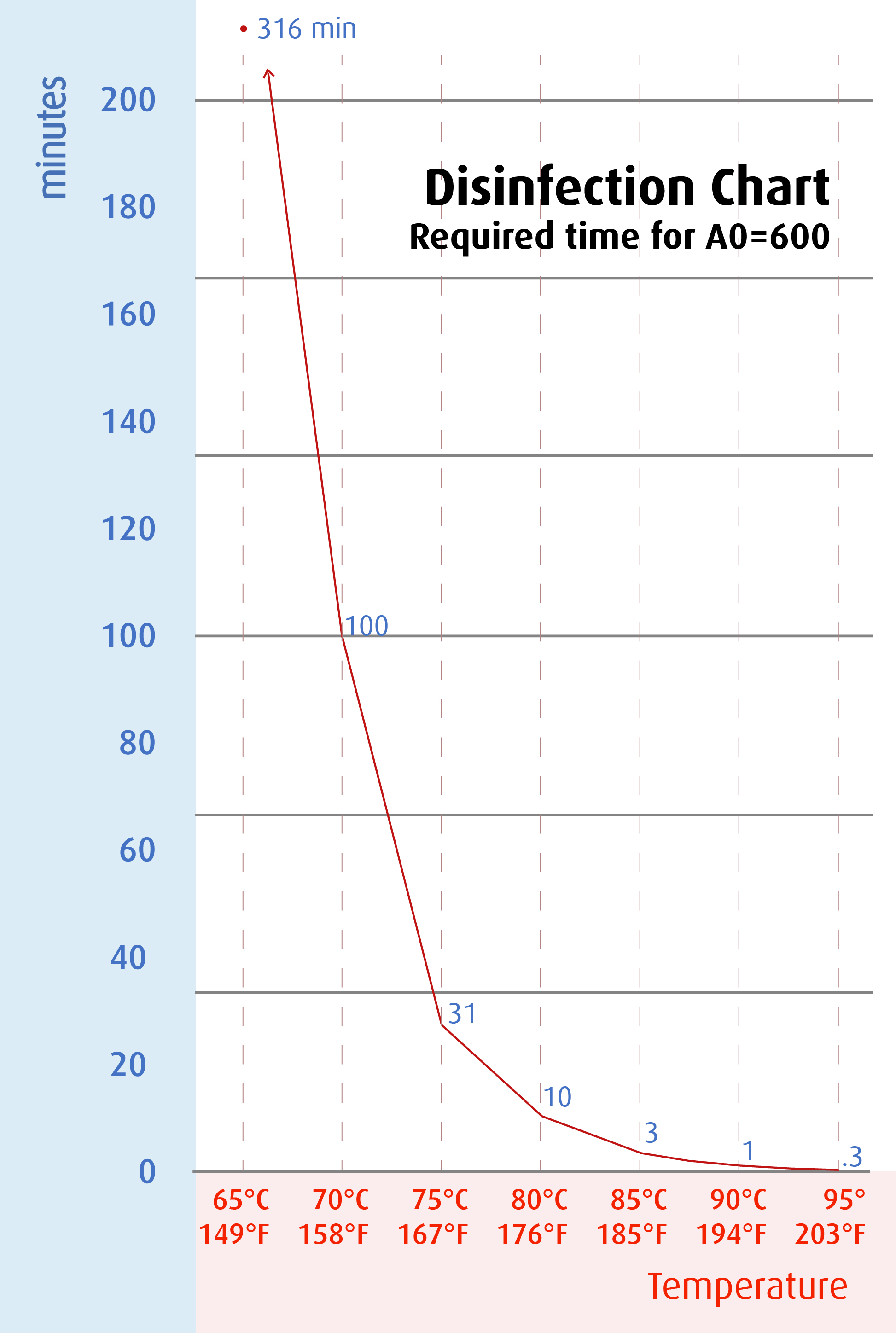

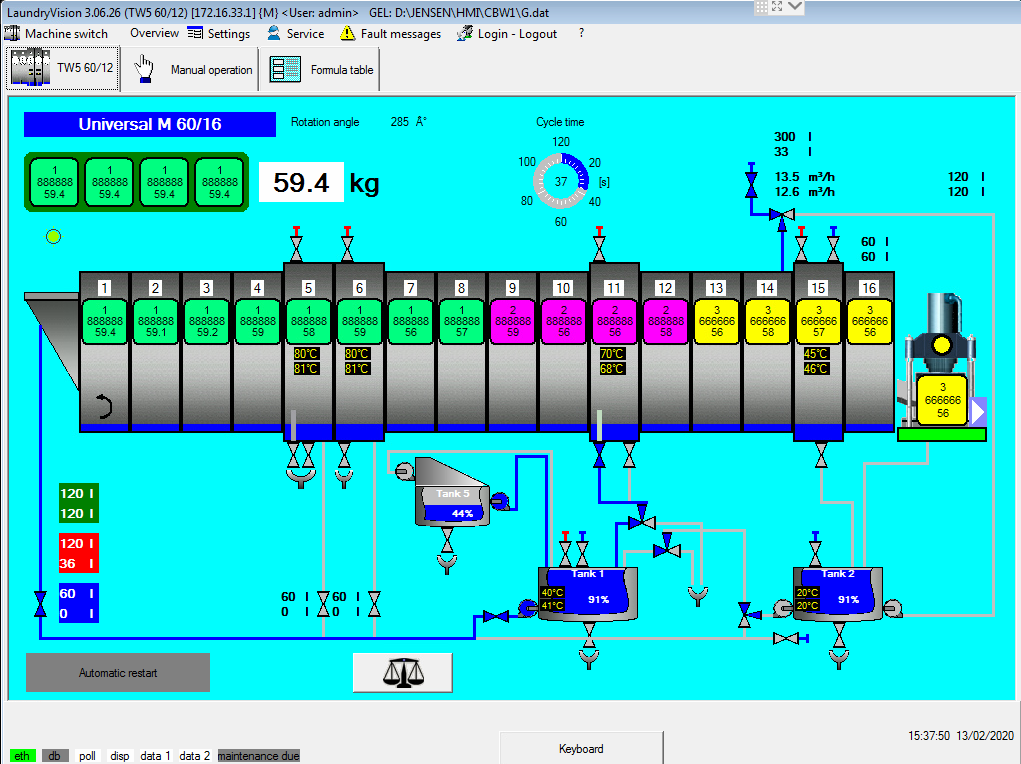

Exposure to high temperatures is necessary to disinfect linen. By increasing temperature or increasing the exposure times to a high temperature, one can achieve higher levels of disinfection. An automatic monitoring of temperature and time in the main wash zone by means of an electronic thermometer measures the real liquor temperature on the last main washing compartment and transmits it by remote transmission to the control of the tunnel washer. In this way it can be checked whether a pre-defined temperature at the beginning of the main wash has also been maintained for a defined period of e.g. 10 minutes until the end of the main wash. Requirements for disinfection differ regionally, but for the minimum requirement to start the disinfection cycle the linen should reach 75°C (167°F) for 30 minutes or 80°C (176°F) for 10 minutes.

Actual temperature vs setting temperature

The difference in temperature between the PLC setting and the actual temperature of the linen is common, and without testing equipment it is very difficult to test the temperature of linen inside a drum.

Hot water will naturally cool down until it reaches the surrounding temperature. This happens in a cup of hot water as well as in your main wash section of your tunnel washer. Different kinds of insulation around the inner drum will also have different insulating results. In colder months, the surrounding temperature is colder and can have a greater effect on the temperature decrease.

It is also important to remember, as hot water comes in contact with pipes, machine, and linen, it cools down too. The PLC is reporting the temperature of the sensor on the tunnel drum, it is not giving a reading of the actual temperature of the linen inside the tunnel—and this is the only thing that matters for disinfection.

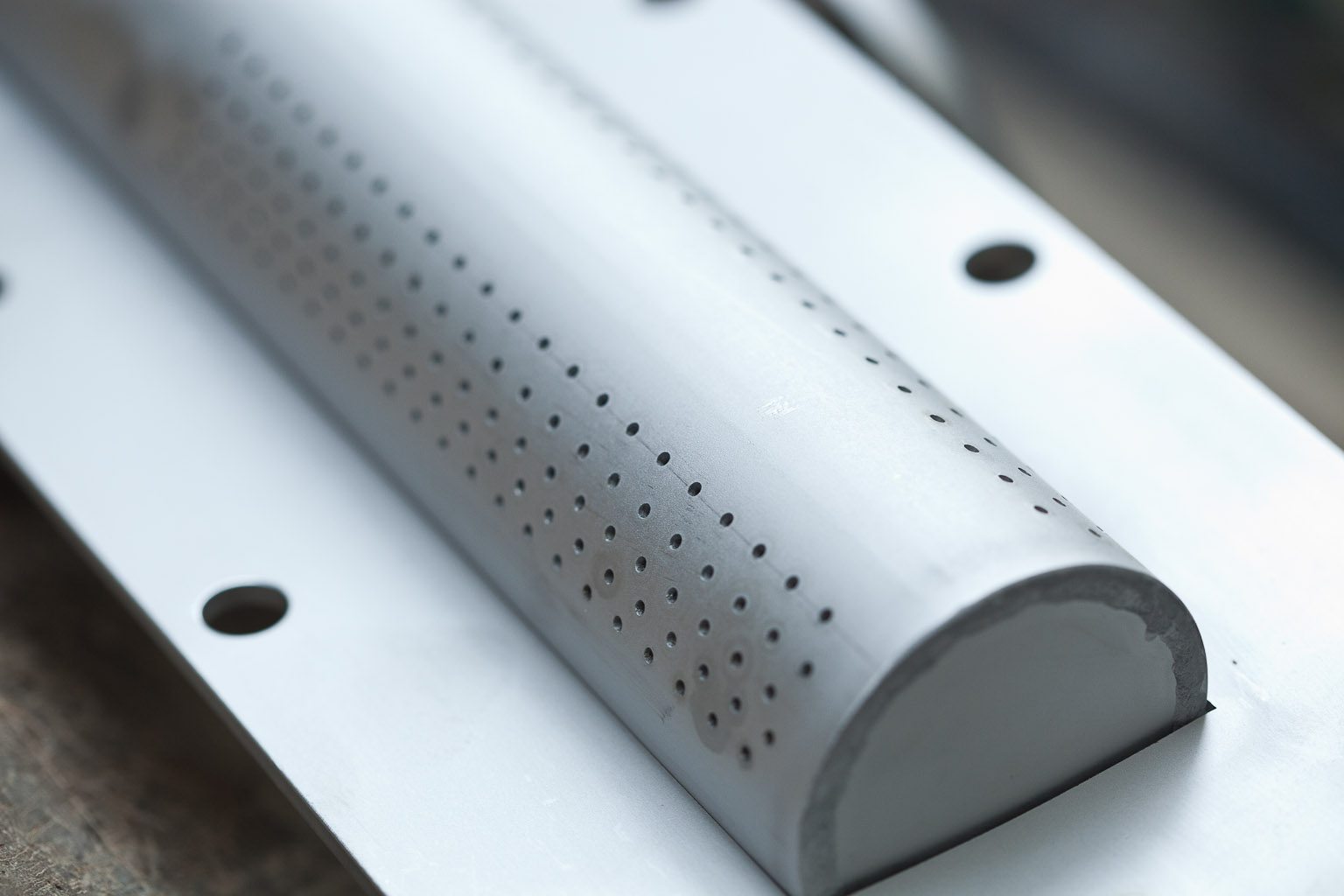

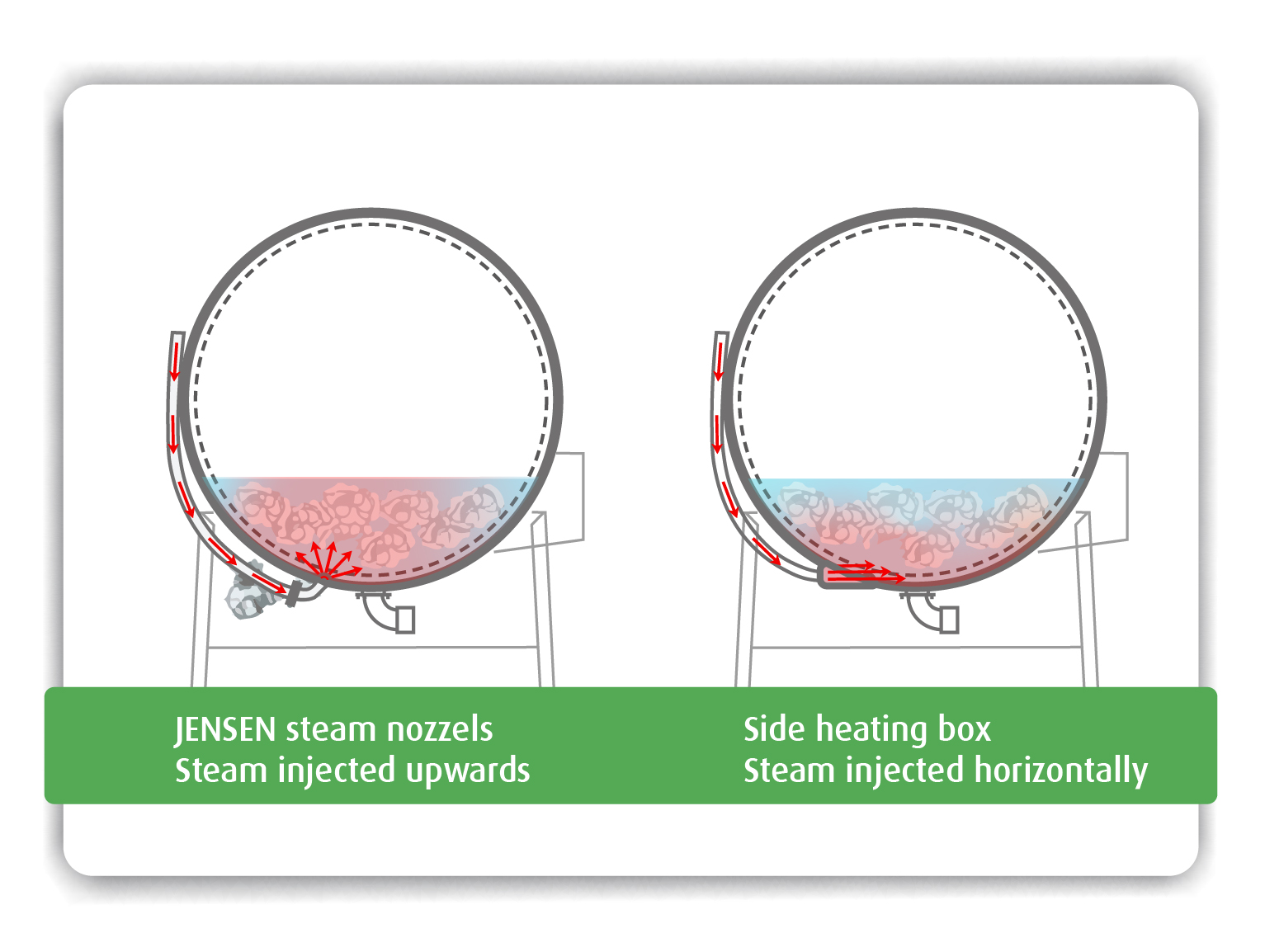

JENSEN tunnel washers offer a quick and even distribution of the steam/heat into the batch, which is only possible thanks to specially developed steam injectors. This process is much more efficient than machines that heat the water underneath the drum. Only heating the water under the drum can lead to uneven or falling temperature curves as the hot water mixes with cold linen. It can also lead to significant temperature discrepancies between the linen at the center and the PLC, as the PLC thermometer only reports the water temperature on the outside of the drum.

Test your temperature

It is crucially important to guarantee two things: first, that the linen reaches the required temperature, and second, that it maintains that temperature for the required time. This should be the most basic quality standard for all laundries, especially during this time, and the only way to really guarantee this is to test.

How to test?

There are many RFID temperature testing devices in the market. The device can be washed together with the linen, and thus more accurately records the temperature of the linen. It records a temperature reading every ten seconds. Running the test a few times in your tunnel washer can help you determine the temperature behavior of your tunnel and any difference between the linen and PLC temperatures. For maximum quality control, this test can be conducted seasonally.

JENSEN Tunnel washers offer quick and even distribution of the steam/heat into the batch, which is only possible thanks to specially developed steam injectors.

The A0 value represents a certain disinfection achieved by a specified temperature. A0 = 600 is stipulated as the minimum requirement for the disinfection cycle.

The PLC on JENSEN tunnel washers – these machines have earned a name for delivering high quality and high consistency in wash results.

The Sinner Circle illustrates the 4 main components that effect wash quality: Mechanical Action, Chemicals, Time and Temperature. As an integral part of the wash process, the importance of temperature cannot be ignored.

JENSEN tunnel washers inject steam upwards directly into the drum compartment.