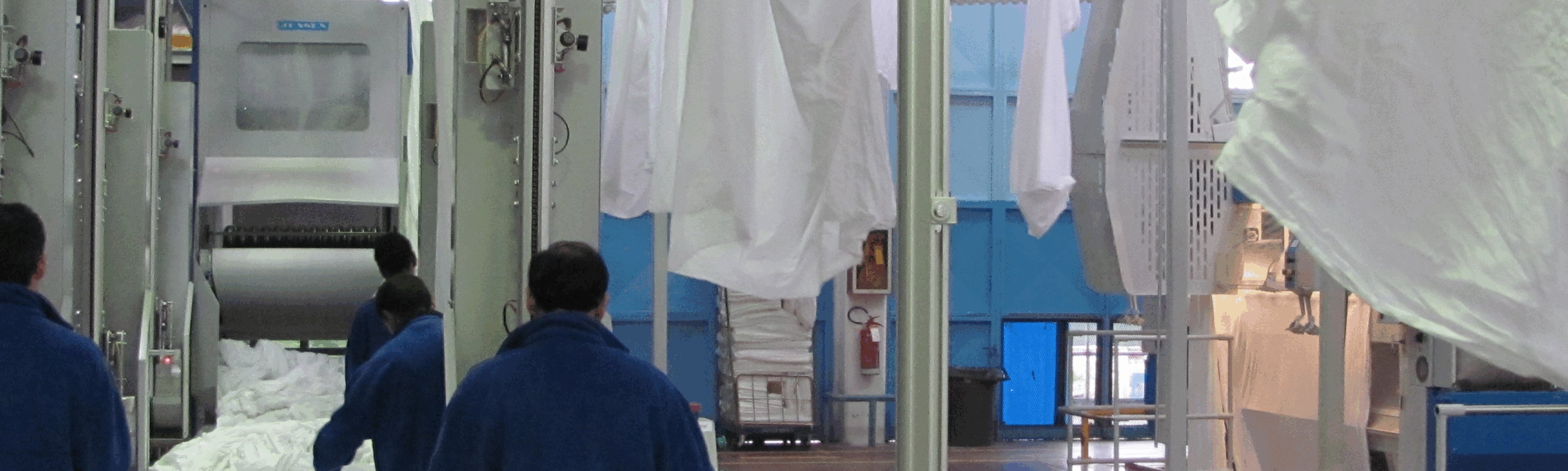

Decentral feeding with Jenrail 2000 Automatic

ニュース&イノベーション

Tourists and honeymooners travelling to Venice are about to experience a new level of comfort in the city of romance: the luxurious bed linens by Pedersoli Group are now processed by the new modernized laundry "Hotel Service Venice", equipped with equipment from JENSEN.

Premium travel agencies promoting luxury accommodations in Italy actually mention the brand name of the bed linen next to all other amenities. "Bed linens by Pedersoli" is a brand promise for those tourists that seek ultimate comfort during their stay away from home. Also in the heavy-duty laundry industry, the name Pedersoli rings more than just one bell: Throughout the years, Pedersoli has become an industry benchmark when it comes to the processing and finishing quality of hospitality linen.

The Pedersoli family owns a network of laundries throughout the country. The "Hotel Service Venezia" is located in Mestre, a suburb of Venice. On November 22, the laundry celebrated its 10th anniversary. On the same day, they also inaugurated the new equipment that was also installed by JENSEN. The JENSEN equipment takes care of the entire laundry process, including the washroom itself, the logistics of moving linen and textiles, as well as the finishing with feeders, ironers and folders.

Futurail - The GPS system for your laundry

On the soil side, the linen is received, sorted and stored by means of a Futurail system.

Futurail automates the terry towel handling and storage process, from reception of soiled linen to the finishing stations on the clean side. In the reception area, unsorted soiled linen is rapidly unloaded and taken to the sorting area, where it is sorted, weighed or even counted. These loads are stored before arriving in the washroom section. Futurail sorts by customer, finishing category and washing program, putting soiled linen into stainless steel containers. Once a load is complete, bags are loaded from these containers, classified, and then automatically conveyed to the soiled linen overhead storage.

First stop: Washroom area

Three Senking tunnel washers, among which one brand new Universal M-14 processing 60kg (130 lb.) batches, process a total of 40 tons (80,000 lbs.) of linen per day, in an 8-hour operation. Tunnel washers from JENSEN can be configured to meet individual customer demands; however, they all share one common denominator as they combine highest operational efficiency with lowest media consumptions. Excellent wash and rinse results are self-evident; guests from premium lodgings would not accept anything else. Together with the new tunnel washer, a new 51-bar high pressure press extract the water, and six DT 140 gas heated dryers equipped with infra-red, controls the perfect drying of these luxury terry towels.

Finishing area: High productivity thanks to decentralized feeding

The Jenrail Automatic 2000 remote feeding system for sheets and duvet covers automates the feeding of the subsequent finishing lines for large pieces. A buffer of washed and sorted laundry before a fully automated feeding machine compensates for temporary production stops, as well as over-feeding of linen to the production lines. This ensures that the capacity of the feeding machine can be used to its fullest capacity. Two Jenfeed Logic Plus automatic feeders for sheets and duvet covers are complemented by three finishing lines for small pieces, as well as towels.

The new laundry is already up and running to the full satisfaction of our customer.

"The winter season is usually very busy in Venice. Tourists from all over the world love to spend the days around Christmas and New Years in our beautiful city. Also carnival is approaching soon." says Mr. Pedersoli, owner of Hotel Service Venezia. "We are delighted that we can offer the best quality in bed and hotel linen to the many visitors that prefer to stay in one of the splendid hotels that are supplied by our laundry."

Laundry technology supplied by JENSEN means the highest added value you could only dream of. However, it is not a dream: If you wish to explore the magic of Venice together with your loved one, we can guarantee you a peaceful sleep in one of the many hotels that offer linen by Pedersoli Group.