Life Hacks for Laundries

新闻与创新

Life hacks have become very popular in social media….you may have actually tried some yourself. Some are hilarious and sound crazy, some of them are most useful. But are they useful for the laundry business as well? Let’s have a look at the term to check if this is applicable for the laundry industry.

Life hacks refer to any trick, skill or novelty method that boosts productivity and efficiency, in all aspects of life. The term was originally used by IT experts flooded with information overload and those who wanted to speed up their workflow in other ways than programming.

Also in the laundry business, and especially for JENSEN, productivity, efficiency and growth are vital key words. This is what interests’ laundry managers most; how they can grow their business, be more productive and efficient.

There is an array of factors that determine the actual batch size and module count of a tunnel washer. To follow are JENSEN’s 10 “laundry life hacks” on how to make the proper choice:

Step 1: Volume

The linen volume to be processed determines the machine size. This leads to a certain batch size and number of compartments, and with a very high linen volume, two or more tunnel washers are the right choice. For small batch sizes, a Senking Universal tunnel washer P 36 processes 36 kg / 80 lbs per chamber, the largest volumes of 120 kg / 260 lbs are handled with the Senking Universal MaxiLine.

Step 2: Linen

There are various linen types which determine the tunnel washer configuration, such as healthcare linen and linen for nursing homes, hospitality, industrial uniforms, dust mats or cleaning mops. All these different types of linen require a special process:

Uniforms or industrial workwear might require extra bath exchange facilities in the pre-wash or more wash beaters for more mechanical action.

Dust mats with a lot of sand and particles need special recovery tanks to collect the residual dirt. Light and voluminous items like underpads from hospitals or nursing homes are often underloaded which has an impact on the machine capacity and therefore the size of the tunnel washer. This is also valid for polyester and blended fabric items.

Step 3: Soil Level

Heavily soiled linen and garments are recommended to have extra bath exchanges or need more mechanical action. For greasy items, a high pressure cleaning system with double drums is recommended to clean after processing oily and greasy goods to avoid contamination of following batches. Soiled linen requires longer wash times, which has to be considered when sizing the machine. All Senking Universal tunnel washers are suited to cope with longer wash times with high mechanical action because of its unique drum design; the Archimedian screw offers a highly stable construction. Lightly soiled items can be processed faster compared to other linen categories which increases the capacity of the tunnel washer.

Step 4: Colors

Laundries processing linen of different colors may have a series of color changes during the day. For frequent changes a bath exchange rinsing is perfect to process different colors directly one after the other for highest flexibility and efficiency. The bath exchange rinsing is available for many Senking Universal tunnel washers.

Energy and water savings become more and more important as resources are limited and will become more expensive. This will also effect the profitability of the laundry. To keep the water consumption low in spite of frequent color changes in the process, additional recovery tanks for a separated reclaim of white or colored water in large dedicated buffer tanks is an advantage.

Step 5: Work order

The work order and how the entire volume can be processed through the tunnel washer system has an impact on the machine design as well. Laundries are often faced with little or no space in front of the machine for a loading step conveyor. Think high, use the space under the roof and increase the productivity of the tunnel washer by optimizing the loading process. With a Futurail sorting and storage system, the logistics and batch flow can be optimized and adjusted to specific production requirements. This results in a continuous loading of the tunnel washer without any idle times. If available washroom space is an issue, the Senking Universal CompactLine could be the perfect solution: It combines all advantages of a tunnel washer with a small footprint.

Step 6: Process

Special wash processes influence the configuration of the tunnel washer. A longer or shorter pre-wash, main wash or rinse zone depending on specific requirements are important parameters.

Special disinfection processes are also important to consider, whether thermal or chemo-thermal, depending on the linen type and hygiene requirements.

If the tunnel washer is to be linked to external systems, like water heating systems, water recovery and treatment systems, external filters or energy recovery systems, then the tunnel washer needs to be configured to enable these interfaces.

Based on the preferred heating system, the tunnel washer needs to be laid out for either steam or gas heating.

Step 7: Space

Laundry buildings can be very different. Space, height and many other local parameters determine the machine choice, for example less compartments but larger batch size to reduce the length of the machine.

Also turnkey projects have their prerequisites which have to be considered. Quite often, the tunnel washer has to be linked to existing systems like a monorail system that might determine the batch size and the configuration of the tunnel washer beforehand.

Step 8: Customization

Tunnel washers are always a unique solution: They can be adapted to local requirements to boost their productivity.

Many options and features to consider that could increase its efficiency:

• Integrated heat recovery from waste water to pre-heat the fresh water, if there is no central heat recovery unit in the plant.

• QuickSoak provides an extra shower in the first compartment for categories with a tendency to float (e.g. underpads, diapers, uniforms, polyester items) to improve the soaking and increase the pre-wash effect.

• Additional EcoTanks for laundries processing both dark and light colors and with the demand for both highest flexibility and lowest water consumption.

• For an even higher wash quality, process monitoring systems like EcoSafeguard control the rinse process and the fresh water supply together with its hardness to assure highest quality for a brilliant result.

Step 9: Security

Profitability, growth and investment security - these are the three key aspects that each entrepreneur in all business sectors is striving for. Also laundry managers planning to invest in a new tunnel washer are looking for technology that helps growing their business in a profitable, sustainable way - in a way that secures their investment in the long-term. The security of working with the right partner for the long term, with the ability to obtain all equipment and services for the laundry from a full range supplier like JENSEN is a key to secure the investment.

Step 10: Passion

The tunnel washer is the heart of the washroom section of the laundry which requires passion to do a great job. Knowledge, engineering expertise, commitment and perseverance, as well as the competencies that go hand in hand with these qualities, characterize the passion for laundry solutions that all employees within the JENSEN-GROUP share. With JENSEN, you have the security of a strong partner to obtain all machines, all materials handling, all automation from one company - a company that supports you throughout all phases, from offer to commissioning.

Every step you take …

How-to guides are loved by everybody. JENSEN loves going through a project step-by-step together with you so you can spend a weekend doing something awesome.

These 10 “laundry life hacks” shall guide you through the tunnel washer jungle – and lead you to the one tunnel washer that will boost the productivity in your laundry.

A JENSEN Senking tunnel washer is always the right choice – Tuned to perfection in 10 easy steps.

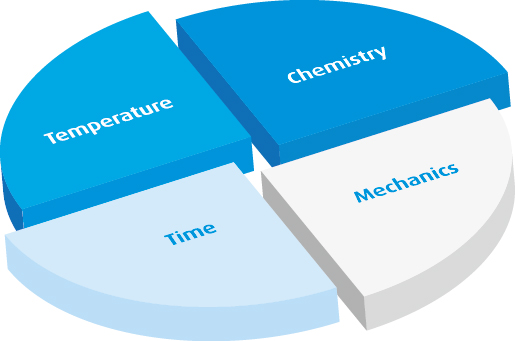

Sinner’s Circle: Only when all four factors are harmonized, an optimum washing result can be achieved in the process.