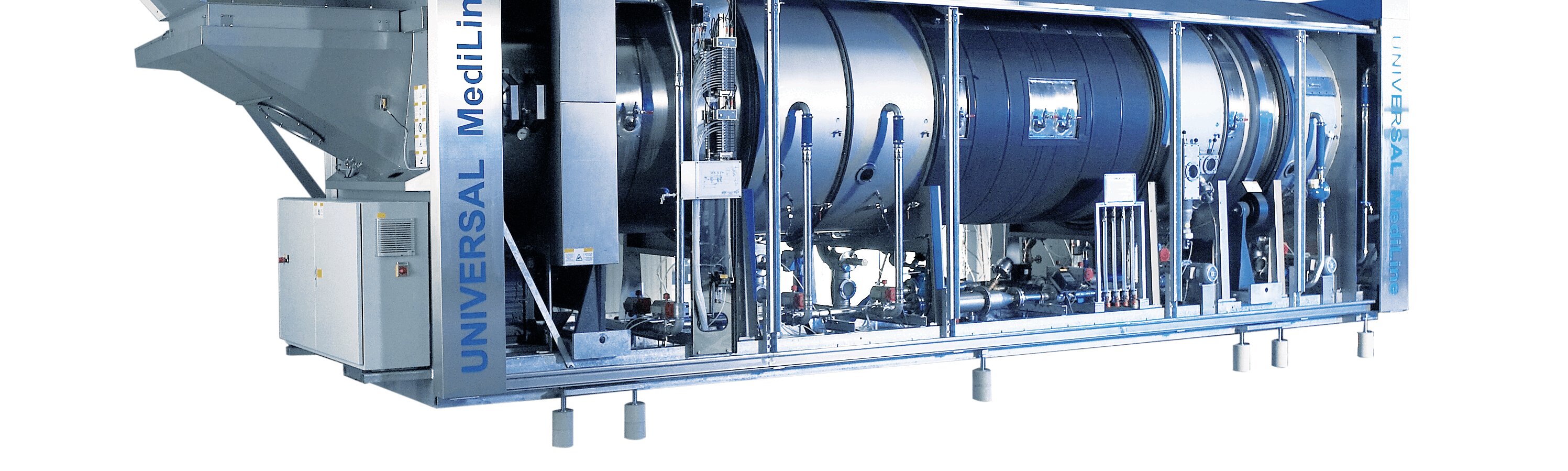

The first and only tunnel washer certified in accordance with Class 2a of the Medical Devices Act. The machine is shown without protective cover.

新闻与创新

In medicine and everyday life settings, hygiene practices are employed as preventive measures to reduce the possibility of incidence and spreading of disease. Now, that we all are facing the COVID-19 pandemic, we must be sure that professionally processed linen which we come in contact within hospitals or nursing homes is absolutely clean, sterile and germ-free. JENSEN’s Senking MediLine tunnel washer meets the highest clinical and hygienic requirements and is the only one in the industry that is certified according to the German Medicinal Devices Act (MPG) and the European Medical Device Directive (MDD).

When talking about hygiene, we think of cleanliness and keeping surfaces in the home and workplace clean and sterile, and of course, nowadays to wash and disinfect hands very regularly. Cleanliness and hygiene are essential for a healthy life. Even in ancient times, people were aware that there is a connection between hygiene and health: The word “hygiene” itself means "good for the health”. According to the World Health Organization (WHO), "Hygiene refers to conditions and practices that help to maintain health and prevent the spread of diseases”: In summary, hygiene is a concept related to cleanliness, health and medicine - and plays an important role in the laundry business and begins as soon as the linen arrives in the washroom section.

During the wash process, temperature and detergents work to reduce microbial contamination levels on the linen. Soil and microbes from fabrics are severed and suspended in the wash water. These are then "washed away" during the rinse process. In addition to physical removal, micro-organisms can be killed by thermal inactivation which increases as the temperature is increased. Chemical inactivation of microbes by the surfactants and activated oxygen-based bleach used in detergents contributes to the hygiene effectiveness. Especially in hospitals and nursing homes, the linen must be absolutely clean and germ-free. An official certificate gives ample proof of this.

Certified according to the Medical Device Directive

JENSEN’s Senking MediLine tunnel washer meets the highest clinical and hygienic requirements without reclaim tanks and is certified according to the German Medicinal Devices Act (MPG) and the European Medical Device Directive (MDD). Some years ago, JENSEN developed the MediLine tunnel washer in line with the increasing hygiene requirements that have come about in recent years – and it became more relevant than ever.

The current prevalence of germs and bacteria, and of course viruses, is resulting in the hygienic requirements and legal regulations found in most areas of life becoming increasingly stringent, particularly in the field of hospital supply products. The Senking MediLine is a systematic development of the patented SL principle, in which neither the tunnel washer nor the extraction press has a recovery tank. By eliminating recovery tanks and using only one or two central pipelines, dirt and bacteria build-up are avoided. All pipelines are also made from stainless steel, effectively preventing corrosion and contamination. The amount of maintenance required is much less since there is no need to carry out the regular and often difficult task of cleaning tanks. All this results in a much faster process.

Furthermore, the Senking MediLine has particular technological features that make it truly unique when it comes to handling hospital textiles in accordance with the Medical Devices Act (MPG). This Act stipulates that the same regulations apply to reusable surgical materials that have been processed in a tunnel washer as for the preparation of surgical instruments. The MPG falls under the Medical Device Directive, which is valid across Europe.

The patented SL Wash Principle: 100% Hygiene, 100% Success

As the Senking MediLine is based on the patented SL principle, it also uses the same well-known bath exchange process with standing baths in the pre-wash and clear washing zone. This is the prerequisite for achieving a high level of flexibility, while at the same time, keeping operating costs as low as possible. Its water recovery rate is higher than in other tunnel washers with buffer tanks thanks to targeted, compartment-specific wash liquor recovery in the pre-wash and clear washing zones. The direct water recovery results in a significant reduction in heat losses, which frequently arise as a result of using a buffer tank. All water flows and volumes are recorded and controlled with the greatest precision by inductive water meters. The highly effective mechanical action is ensured by various parameters that can be adjusted freely for each washing program – for example, the bath level, drum rotation speed and pivot angle – along with the eccentric, washboard-shaped Archimedean helix and high ribs. The MediLine carries out thermal disinfection of the entire machine with the option to completely empty the system before extended standstills. Special program routines thermally disinfect the pre-wash and clear washing zones, as well as the rinsing zone and the finishing compartment, at the touch of a button once the last batch has been loaded so that the entire machine can then be emptied completely. Furthermore, not only is the water required for the pre-wash dispensed with the greatest precision from the recovered wash liquor using inductive measuring technology, moreover the programmed temperature is also monitored by a special transponder system.

Temperature’s role in disinfection

Exposure to high temperatures is necessary to disinfect linen. By increasing temperature or increasing the exposure times to a high temperature, one can achieve higher levels of disinfection. An automatic monitoring of temperature and time in the main wash zone by means of an electronic thermometer measures the real liquor temperature on the last main washing compartment and transmits it by remote transmission to the control of the tunnel washer. In this way, it can be checked whether a pre-defined temperature at the beginning of the main wash has also been maintained for a defined period of e.g. 10 minutes until the end of the main wash. Requirements for disinfection differ regionally, but for the minimum requirement to start the disinfection cycle the linen should reach 75°C (167°F) for 30 minutes or 80°C (176°F) for 10 minutes.

If the liquor temperature for the pre-wash is higher than the limit that has been set, an automatic safety routine is promptly activated so that cold, fresh water is used instead of the overly warm wash liquor. This effectively prevents any coagulation of protein such as blood on the linen. Specially designed overflow boxes guarantee a simple cleaning process and optimal lint removal – perfect for hospital linen to avoid that lint may get into wounds.

Equipped for the future

To date, the JENSEN Senking MediLine is the first and only tunnel washer to be certified in accordance with Class 2a of the Medical Devices Act. The certification was carried out by one of the leading test laboratories for hygiene, which is accredited to provide hygiene certification for tunnel washers. With the Senking MediLine, all laundries can rely on immaculate, hygienic linen at all times, which is more important than ever.

We all like to rely on perfectly cleaned and disinfected linen in a hospital.