新闻与创新

More than ten years ago, JENSEN revolutionized the laundry market by adopting a CleanTech approach. One of major resulting evolutions to the market was that gas heated industrial laundry solutions became readily available - and in many regions quite common. However, this revolution did not reach all the laundry markets of the world, and steam has continued to dominate the laundry industry in the developing laundry markets in Asia, South America, etc. This may now change, as value-engineered gas-heated solutions are offered as an alternative to high-end products.

Higher temperatures and better temperature control

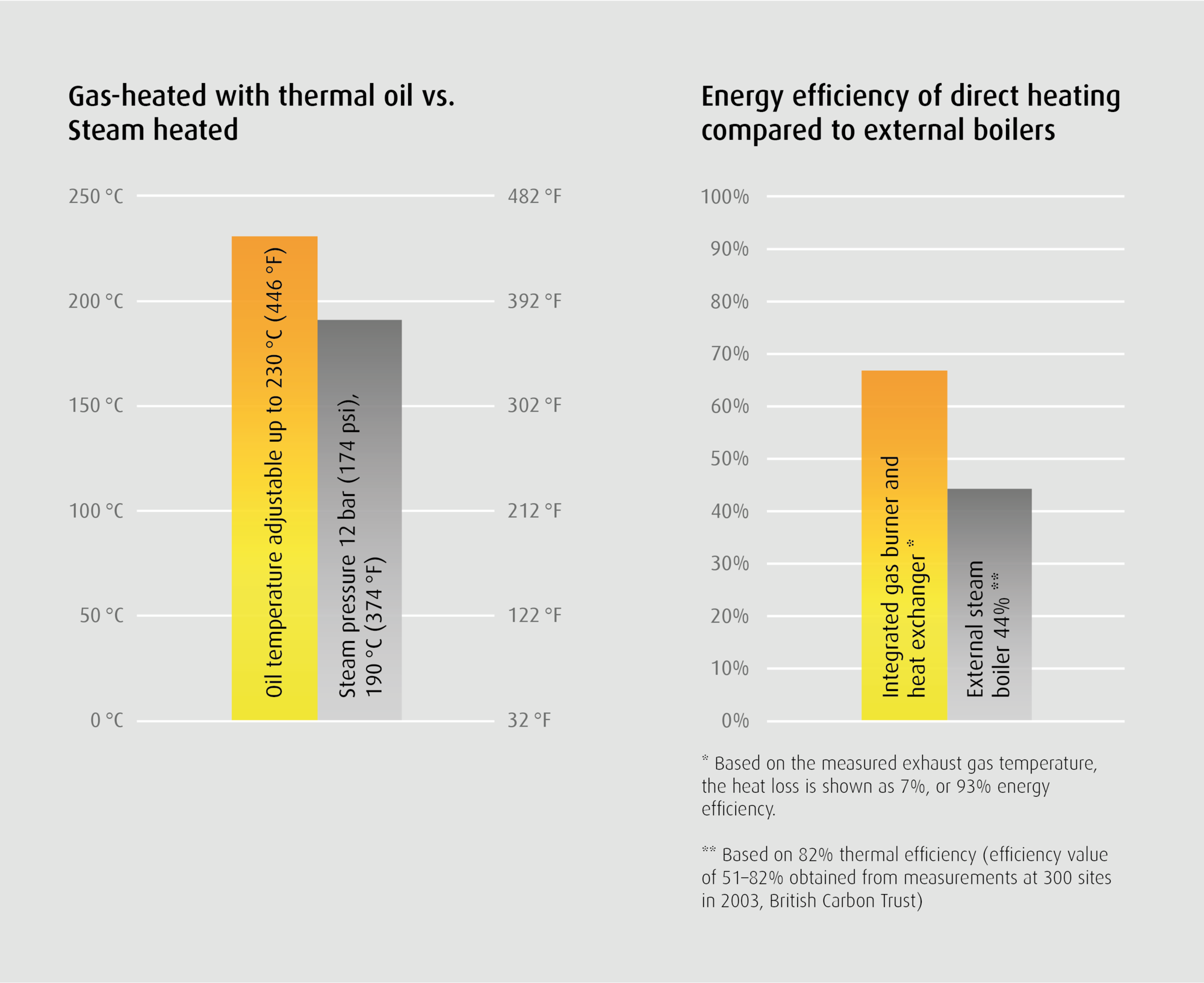

Burning natural gas can replace steam as the heat source in dryers and ironers. It is a hotter heat source, and because you can change the flow speed of gas to increase or decrease the flame size, gas also allows for better and more precise temperature control.

Higher quality and more efficient production

Ironing temperatures can be set close to the maximum allowable temperature for each linen type, allowing for a faster and higher quality ironing result. For dryers, higher temperatures will dry linen faster, increasing production speed and in some cases, reducing the number of necessary dryers.

Liberation from steam

Steam is an excellent heat source, but only if it has enough pressure, if it is high quality, and of course if it is available. Simply put, steam is not always the solution for laundry heat. For laundries that do not have readily available steam, and are already using gas to heat a boiler, then it is significantly more efficient to directly heat the machine. If installing your new equipment addition requires an expensive extension to an existing system, then you should consider gas solutions.

You save costs: Your energy bill will go down

The amount of heat energy lost through steam heating is significant. With steam, in addition to heating the equipment you need, you must also heat an entire steam system from the boiler to the machine. Heating anything other than a machine is operation is a complete waste of energy and money. Furthermore, the whole system is either ON or OFF, and you must maintain steam pressure in all supplying pipelines throughout production. Even when operating a limited number of machines, the whole system continues to lose –and to waste—the same amount of energy.

On the contrary, gas heated equipment has the heating source right where it needs to be, at the machine. Properly insulated gas-heated equipment maintains temperatures, so they can quickly and efficiently heat up in the morning. When you operate individual machines, you use only the required energy for the specific equipment in production. In short, losing less heat energy which means using less heat energy to do the job—making gas heating good for your bottom line as well as the environment.

Gas-heated equipment is available from both ranges of the JENSEN-GROUP, the high-tech JENSEN branded machines and the value-engineered machines under the ALPHA by JENSEN brand. Thanks to this variety of high-quality gas-heated solutions, more and more laundry owners around the world are benefiting from the advantages of gas-heated equipment.

Flexible chest gas-heated ironers with thermal oil offer adjustable ironing temperatures, allowing production at higher or lower temperatures, depending on the requirements of the linen type.

All JENSEN made gas ironers are fitted with an automatic temperature control for optimum production and safety.

Each machine is equipped with its own burner.

Stuhl-Bruck in Austria opened in 2008 using only JENSEN machines and became the first industrial steam-fee laundry plant.

Stuhl-Bruck’s gas-heated JENSEN tunnel washer. Stuhl-Bruck, the world’s first steam-free laundry, was launched in 2008 using JENSEN machines, and the JENSEN-GROUP remains a leader in gas heating technology.

JENSEN transfer dryer WR 60-120 is one of the fastest and most efficient driers in the industry. It is available in gas and steam.

ALPHA I5G is a flexible chest gas-heated ironer, offering excellent finishing quality and excellent value. The ALPHA by JENSEN range also provides gas heated dryers.

Gas is also “hot” in professional kitchens: Chefs prefer cooking with gas for the same reasons laundries benefit from gas heating. A gas flame allows cooks to gauge and instantly adjust the heat by altering the flame. This direct heating prevents heat loss and waiting/cooling down times.