Plenty of space for expertise and modern processes: Wäscherei Kellner laundry in Osterode.

新闻与创新

The Wäscherei Kellner laundry has been providing "Höchste Qualität rund um Ihre Wäsche" (top quality when it comes to your laundry) for more than 60 years in Osterode am Harz. Environmental friendliness and hygiene are extremely important to Helmut and Ricardo Tröger. The two managing directors of Wäscherei Kellner laundry have now seized the opportunity to retrofit their JENSEN P50-15 tunnel washer from 2017 with UVClean. The new UVClean system (patent granted in 2020) for JENSEN tunnel washers automatically prevents bacteria growth in double drum areas without having to use any chemicals – it is the most natural, most environmentally friendly, and most efficient way to eliminate germs and bacteria.

The "gateway to Harz" is open for innovation

The picturesque little medieval town of Osterode is also called the "gateway to Harz". The Harz National Park, which is located in the northernmost low mountain range in Germany, is one of the largest forest national parks in Germany and is one of the most popular hiking and ski areas in northern Germany. With its mix of ancient legends and rugged landscape, it is a popular travel destination throughout the year. As a convenient point of departure for those wanting to explore the Harz National Park, the town of Osterode on the sunny southern edge of Harz has a lot to offer in terms of leisure activities.

If you're not afraid of witches casting a spell on you, you can explore sign-posted hiking trails such as the Goetheweg (Goethe Trail) or the Harzer-Hexen-Stieg (Harz Witches' Trail) through forests shrouded in legends and mysterious upland moors. UVClean is no witchcraft – it is the most natural, most environmentally friendly, and most efficient way to eliminate germs and bacteria – also available for retrofitting.

Wäscherei Kellner laundry seized this opportunity – it expanded in the middle of 2019 and gained plenty of space to modernize its laundry with the construction of a new building. The company is part of Zentratex, an association of laundries – this means that it is able to cover orders from across Germany. Thanks to its high level of expertise in the field of textile care, the Wäscherei Kellner laundry has specialized in hospitals, clinics, care homes, hotels, and industrial companies. The two managing directors of the Wäscherei Kellner laundry, Helmut and Ricardo Tröger, have now seized the opportunity to retrofit their two-year-old JENSEN P50-15 tunnel washer with UVClean in order to provide their customers with a top level of hygiene through environmentally friendly processing.

The new UVClean system for JENSEN tunnel washers (which was recently granted a patent) automatically prevents bacteria growth in double drum areas without having to use any chemicals – it is the most natural, most environmentally friendly, and most efficient way to eliminate germs and bacteria. Bacteria can also not become resistant to UV radiation – in contrast to chemical methods. The engineers from JENSEN have once again found an easy, yet innovative way to maximize the benefits to our laundry customers.

Bacterial contamination in tunnel washers

Laundry is usually disinfected in the main washing area of the tunnel washer. Nevertheless, there is the risk in all types of tunnel washers that the laundry will become contaminated with microorganisms once again in the rinsing zone. The reason for this is the bacterial biofilm in the tunnel washer, which forms a perfect breeding ground in areas with a warm and moist environment that are not continuously rinsed with washing water. Disinfection of surfaces inside a tunnel washer is therefore imperative in order to inhibit the growth of germs and biofilms. This is also a very important issue at the Wäscherei Kellner laundry. Below the water level, the inner surfaces of the outer drum are continuously rinsed with washing water. Thanks to the flow mechanics, no microorganisms can build up here and disinfectants can directly act on the surfaces and prevent the colonization of germs. Above the water level, the inner surfaces are not completely rinsed. Due to the temperature, this area is always moist. Splashes of washing water with cleaning agents, washing additives, and starch as well as condensate reach this area. The environment is warm and moist, similar to a steam bath. This climate encourages the growth of microorganisms that build up on surfaces and can form a biofilm. Cleaning of these surfaces within the machine is difficult and costly. Our objective was to eliminate microorganisms on internal surfaces before a biofilm develops.

Inspired by nature, perfected by JENSEN

The solution was both obvious and natural: UV-C rays are a natural approach among the current methods used for dealing with local biofilms. This method is also used in the pharmaceutical industry if treatment is to be carried out against multi-resistant microorganisms, such as when antibiotics are not effective. Microorganisms such as germs, bacteria, viruses, or other pathogens are eliminated and/or their growth is prevented. Compared with other methods of disinfection, this has the benefit that no chemicals are used and there are no problems with regard to environmental compatibility and disposal. UV-C radiation is now used in an increasing number of areas, for example for disinfection in sewage treatment plants, laboratories, air-conditioning systems, swimming pools, and aquariums, as well as in various phases of industrial processing of food and beverages. UV-C radiation is used in medical practices and hospitals in order to sterilize instruments, work surfaces, and ambient air. In 2019, JENSEN presented its UV-C technology for tunnel washers. The patent was granted one year later in 2020.

UVClean also available as a retrofit solution

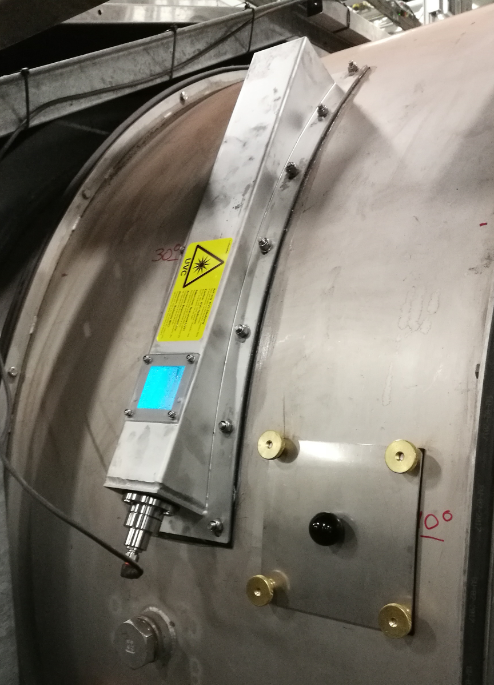

Two UV-C lamps are now mounted in a housing on the outer drum in the tunnel washer of Wäscherei Kellner laundry. They radiate the internal surfaces between the inner and outer drum. Through reflection, the internal surfaces are reached and rid of microorganisms. This is a simple, virtually maintenance-free system with very low operating costs. The two 10-W bulbs have to be replaced after around one year. After 16 months of round-the-clock operation, the UV lamps still provide 75% of the radiation emission. Changing the lamps is very simple – as is cleaning the lamps. Contact samples from the surfaces can easily be taken through two test flanges. This means that it is possible to measure the efficiency of the UVClean system at all times. The light power of the lamps can also be tested through an inspection window.

Practical test passed

The JENSEN development team previously carried out comprehensive tests in a customer's laundry in order to demonstrate how effectively UVClean eliminates bacteria. For this purpose, the JENSEN development team used test samples contaminated with germs. Through the test flanges, the samples were exposed to the radiation source on the outer shell of an outer drum at various distances. They were radiated for a specified period of time.

"We evaluated the reduction in the defined germs on the samples and the total amount of germs and were astonished at the results," states Martin Sukop, Manager Sales in the Washroom Technology Business Unit of JENSEN. "We are therefore able to highly recommend UVClean as an environmentally friendly and groundbreaking method for eliminating germs, bacteria, and biofilms in tunnel washers. It is a simple, virtually maintenance-free system that safeguards laundries against various problems."

As a certified company with the wfk-seal, the Wäscherei Kellner laundry takes all appropriate steps to implement top and strict hygiene safety. This includes protecting against the transmission of illnesses in the laundry and delivering this in both a clean and hygienic condition. They are also committed to environmentally conscious washing processes that protect the fabrics. The JENSEN Senking Universal P50-15 tunnel washer with UV-Clean as retrofit solution more than ensures all this. This means that holiday visitors to Harz can be sure to be provided with hygienically clean laundry from Wäscherei Kellner laundry – something which will put their minds at ease.

Freshly patented: the UV lamps are mounted on the outer drum.

UVClean, the new economical and environmentally friendly way to eliminate germs, bacteria, and biofilms in tunnel washers.

Sunlight is essential for humans and nature. With UVClean, laundries can also benefit from this valuable resource.

The Harz National Park is one of the largest forest national parks in Germany and a popular holiday destination.