专家网志

Washing has played an important role in the history of mankind for thousands of years. In the course of this history, these processes have constantly evolved, however, the mechanism of action behind these processes has basically remained unchanged. In honour of its discoverer, Herbert Sinner, this mechanism of action is called the Sinner’s Circle.

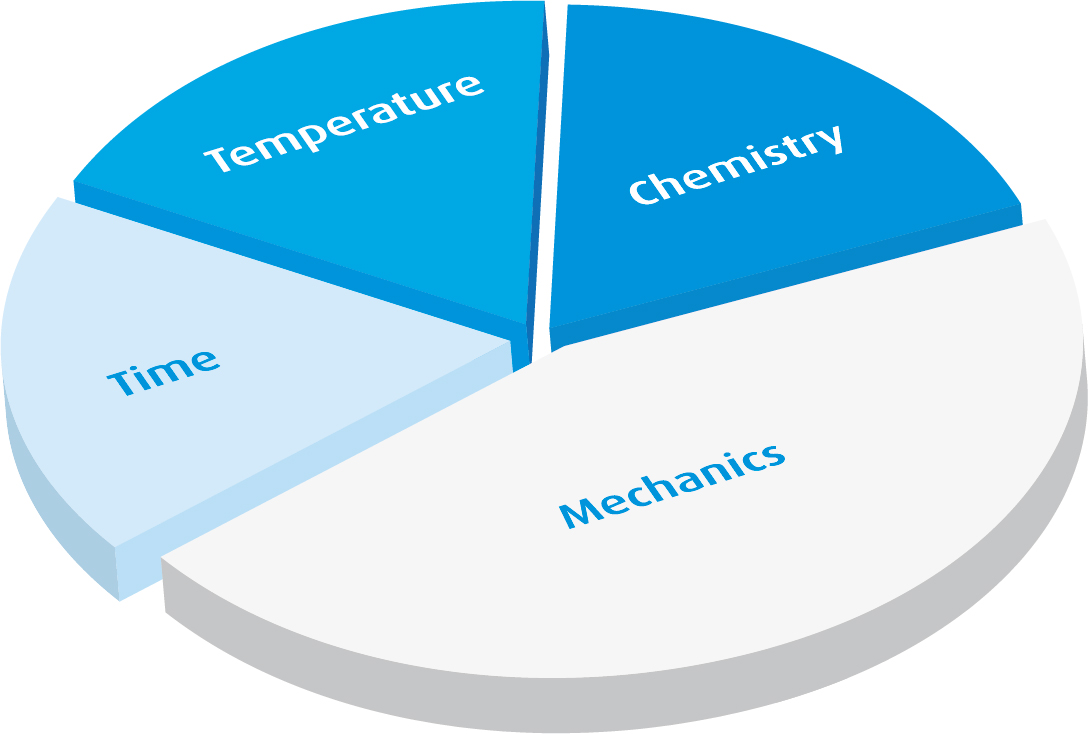

The chemist Herbert Sinner, a detergent chemist born in 1900 in Chemnitz and died in 1988 in Hilden, both Germany, has succeeded in showing the effectiveness of the cleaning power on the basis of four factors. The interaction of these four modifiable basic elements is responsible for an optimal cleaning result. A properly balanced interaction provides the best washing results. These four factors are represented in the shape of a circle, the Sinner’s circle. If any of the factors are reduced, this loss must be compensated for by increasing one or more of the other factors.

The Sinner’s Circle makes the following statements about these factors: They are interdependent. The total sum for a successful cleaning is constant. These two statements show, for example, that a less concentrated detergent can be compensated for by higher temperature, longer washing or increased mechanical effort.

Connect 4: The four factors of the Sinner’s circle

Chemicals, mechanical action, time, and temperature represent the four principle factors that determine the success of a wash. Only all four factors together work in a dynamic team – Connect 4:

1. Chemistry

This refers to the concentration of detergents and washing additives. All chemical elements such as active substances on the linen and water surface with its pH values have an influence on the process.

2. Time

The time that a detergent or washing additive takes to work in the liquid.

3. Temperature

The temperature level influences the cleaning process, hot water will be more efficient than cold water for example.

4. Mechanics

All kinds of physical action, whether if this is a washboard, a helix, wash beaters, high pressure cleaners or brushes.

From theory to practice

Composing the right Sinner’s Circle is extremely important to achieve an optimal cleaning process. Now what does that look like in practice with reference to tunnel washers?

Having a look at the wash times and cycles, special wash processes influence the configuration of the tunnel washer. A longer or shorter pre-wash, main wash or rinse zone depending on specific requirements are important parameters. Soiled linen requires longer wash times for instance. Lightly soiled items can be processed faster compared to other linen categories which increases the output of the tunnel washer.

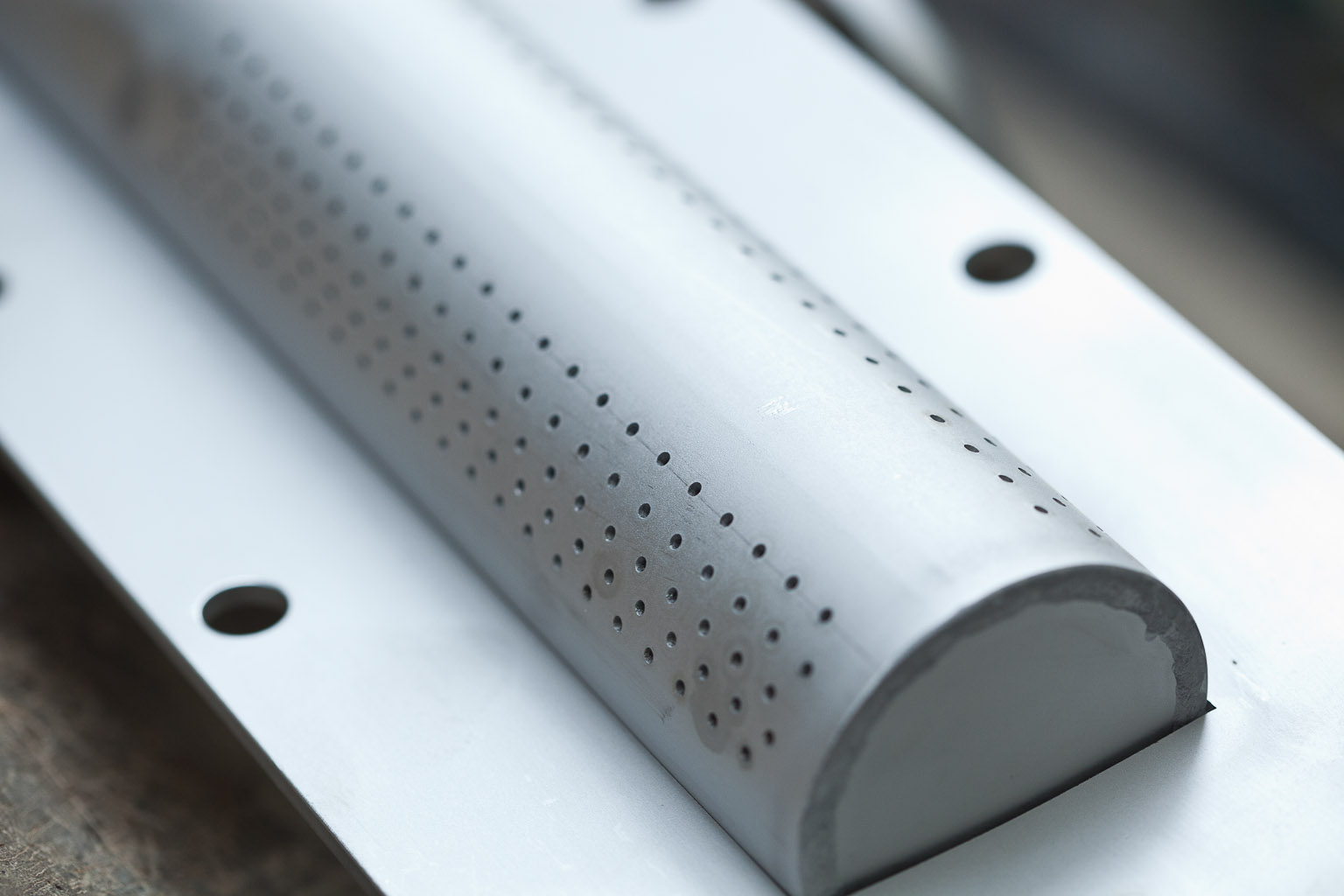

Temperature plays a crucial part of the wash process. If appropriate temperatures are not reached, it could result in dirty or stained linen, or worse: improperly disinfected linen. With a current emphasis on safety and reduced contamination, it is no understatement to stress the importance of guaranteeing the correct temperatures throughout your wash cycle. JENSEN’s specially developed steam nozzles with a large perforation area ensure an energy-saving and fast heating process. This guarantees uniform heat release into the linen with short heat-up times and an even distribution in the batch.

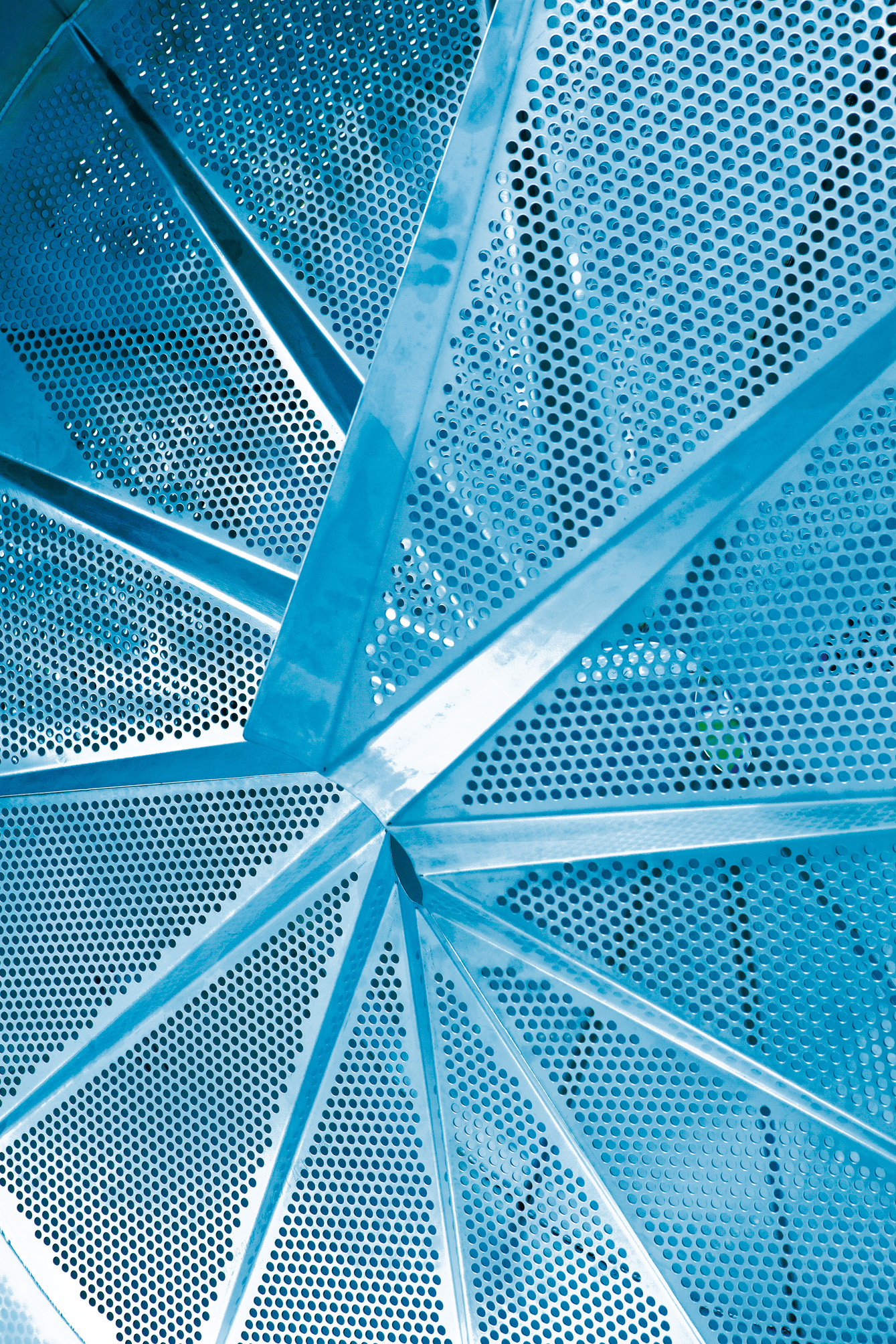

Heavy-duty laundries processing workwear have other challenges than laundries for hospitality linen for example. They run garments in different colors and different types of textiles in the tunnel washer and want to keep water consumption low even if there are frequent color changes. When it comes to heavily soiled linen like uniforms or industrial workwear, tunnel washers with a large drum volume is perfect for their needs. They can all cope with longer wash times with high mechanical action because of its unique drum design. The Archimedian helix offers a highly stable construction and removes the soil with its washboard shape. Extra wash beaters provide even more mechanical action: Perfect for workwear.

In terms of flexibility, efficiency and productivity, the bath exchange process is far superior to classic systems like the counterflow process. The savings in water consumption have a tremendous impact on the KPI. A large drum capacity, high washing ribs, high rotational angle and the washboard like shaped Archimedean Helix generate a high mechanical action. It is thanks to this mechanical wash action that less water is needed to rinse out the detergents. This reflects perfectly a balanced Sinner’s circle for perfect wash results and at the same time a huge amount of saved water. The current benchmark in terms of water consumption is 1.6 l/kg of linen (0.19 gal/lb)!

It’s all about balance

Only in the perfect interaction of chemistry, mechanics, temperature, and time will the cleaning process for each material be successful. Let’s find together the right balance for your linen achieving perfect results – for excited customers.

The Sinner’s Circle illustrates the 4 main components that effect wash quality: Mechanics, Chemistry, Time and Temperature.

The Archimedian helix stands for very high wash mechanics and reminds of a washboard.

Fast and even heat distribution in the batch thanks to special steam nozzles

A JENSEN tunnel washer will adapt the perfect wash process to the specific needs.