Tudor Morar und Martin G. Albøge from Inwatec installing and commissioning the new robot at NT in Trondheim, Norway

News & Innovations

Removing the dirty work in a laundry is a process that was not automated until a very short while ago. A dynamic and young group of laundry nerds in the Danish city of Odense found a solution for that. Inwatec’s automated soil sorting system minimizes the need for human interaction to quality control and surveillance, and consists of an X-ray machine and a learning system.

In January 2018, the JENSEN-GROUP acquired a participation in Inwatec. This investment in laundry robotics and artificial intelligence confirms our vision to automate all processes in the laundry.

How does it work?

Robots pick up the laundry pieces from conveyor belts and transport them to the X-ray scanner, which detects unwanted objects hidden in the pockets. At the same time, an RFID chip reader registers the garment and determines further sorting in the system. All these tasks can now be performed by a small number of operators who only have to empty the pockets of the discarded garments.

Watch it here: https://youtu.be/-oDMVnP__p8

Intelligent robots offer unlimited possibilities

The challenge so far has been to make robots intelligent enough to replace human functions. Artificial intelligence enables computers to analyze huge amounts of data. One example are systems based only on visual sorting. These are mainly used for unmarked garments.

Occupational safety thanks to X-ray technology

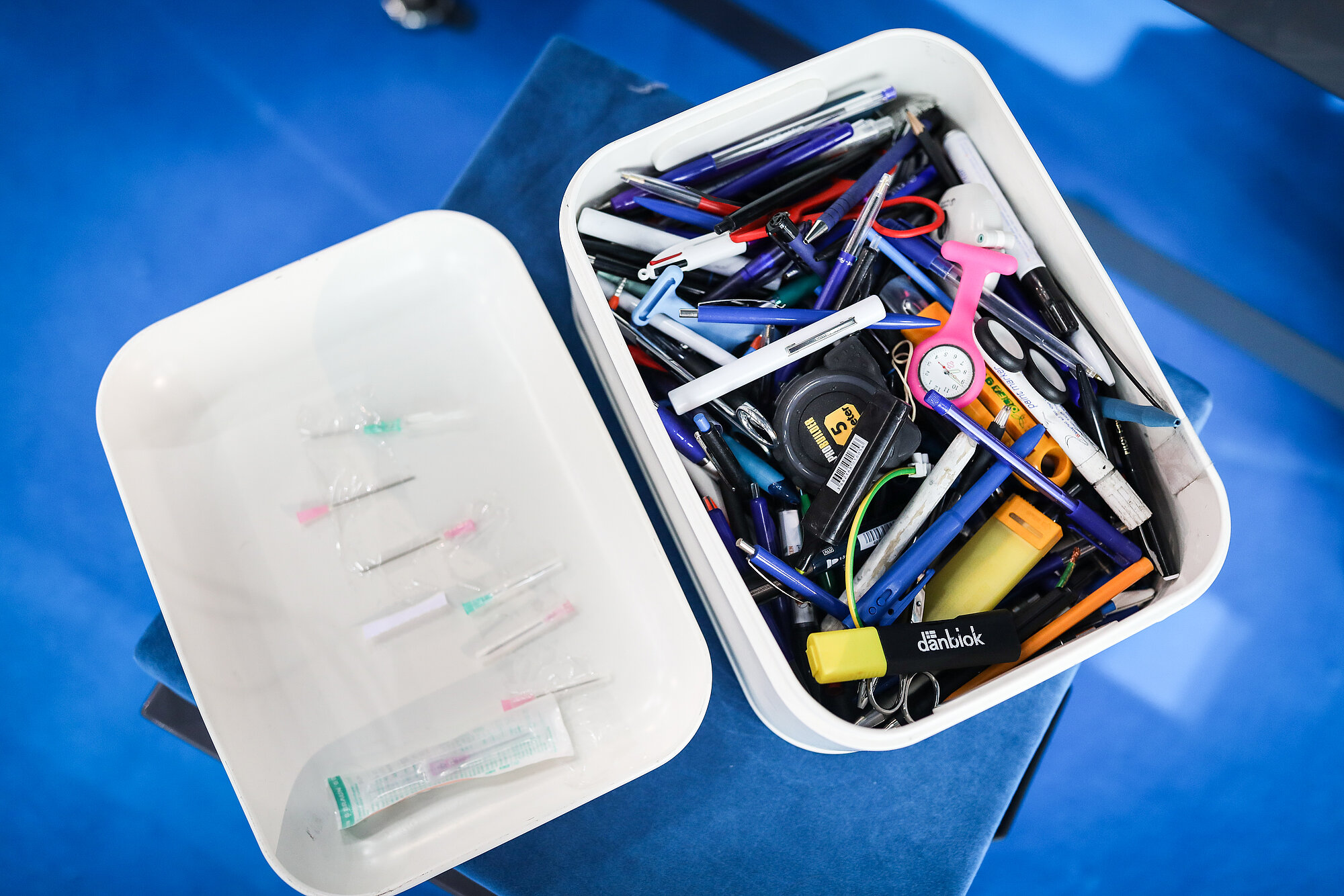

Even as a single machine, the X-ray scanner performs flawlessly: it checks bulk soiled laundry items for dangerous foreign parts and creates a safe and efficient working environment. X-ray technology can detect harmful objects such as tweezers, scalpels or scissors, so that the possibility of stab injuries and infections is zero.

From human intelligence to artificial intelligence

When an average person completes a mental task in less than a second, this process can be automated with artificial intelligence. The laundry industry is now at the beginning of a new era in which technology can take over most of the production processes without human interaction.

Creating the future in laundry automation is definitely happening now: Quite a few laundries all over the world have become pioneers in their field utilizing robots from our partner Inwatec to sort the soiled linen and garments.

A great team of #laundry nerds at Inwatec, Denmark

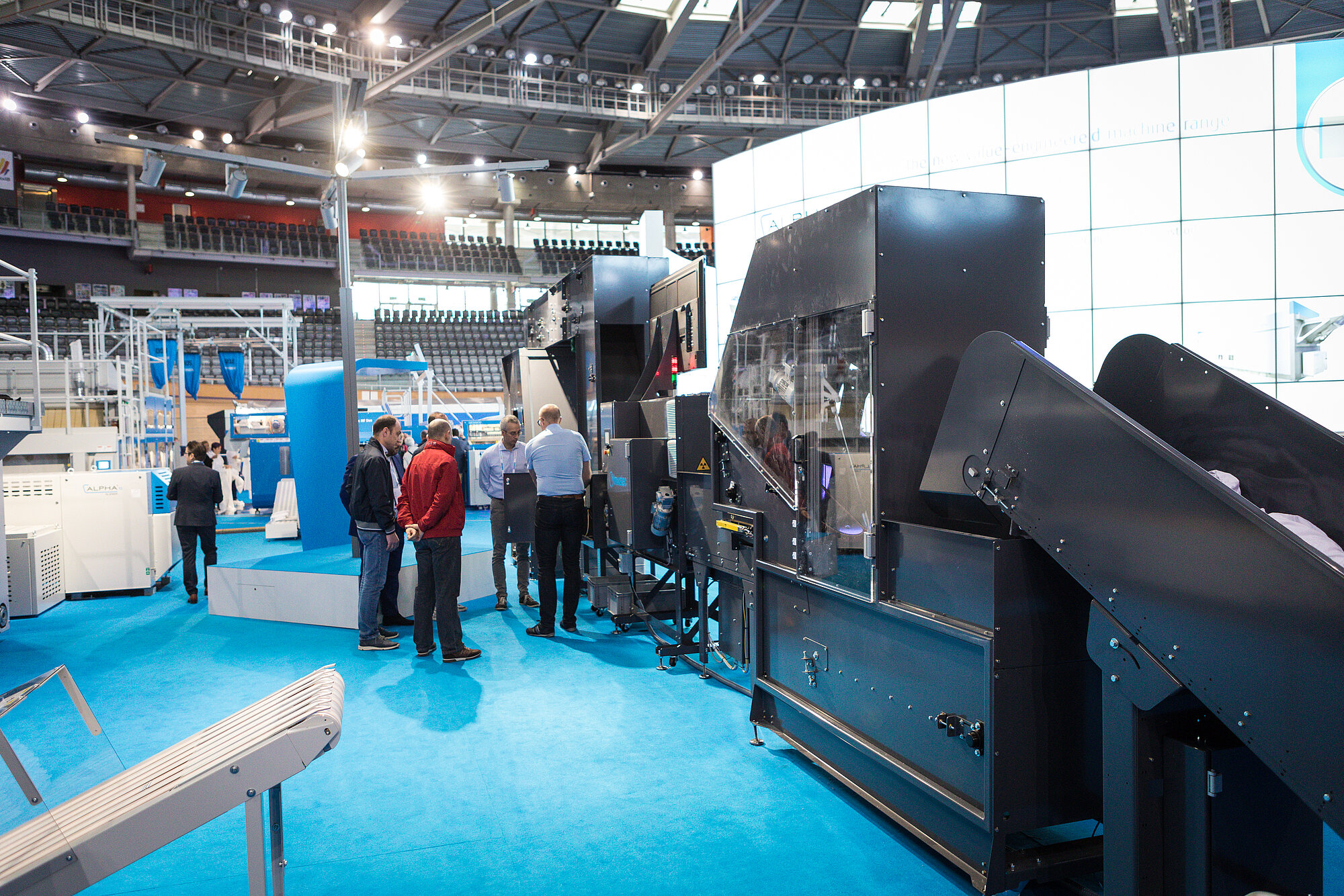

The soiled side sorting system attracted a lot of visitors at our recent JENSEN Performance Days.

A collection of what can be found in pockets – dangerous and partially infected items creating a great risk to the health of laundry operators