Clean, cleaner, UVClean: Presented at Texcare 2024 with fresh certification.

技術的記事

The UVClean system for JENSEN tunnel washers is now patented and certified to automatically prevent germ growth in double drum areas without having to use any chemicals – UV light is the most natural, most environmentally friendly, and most efficient way to eliminate germs. The engineers from JENSEN have once again found an easy, yet innovative way to apply nature’s benefits to our laundry customers.

Bacterial contamination in tunnel washers

A proper washing cycle disinfects laundry in the main washing area of the tunnel washer. Nevertheless, there is the risk in all types of tunnel washers that the laundry will become contaminated with microorganisms once again in the rinsing zone due to microbial biofilms. The double drums of a tunnel washer form a perfect breeding ground for biofilms with a warm and moist environment that is not continuously rinsed with washing water. Disinfection of surfaces inside a tunnel washer therefore eliminates or inhibits the growth of germs and biofilms. This is a very important issue at many laundries. Below the water level, the inner surfaces of the outer drum are continuously rinsed with washing water. Thanks to flow mechanics, no microorganisms can build up here and disinfectants can directly act on the surfaces, preventing the colonization of germs. However, above the water level, the inner surfaces are not completely rinsed. Like a steam bath, this area is constantly exposed to warm moist air and splashes of washing water with cleaning agents, washing additives, and starch. This environment encourages the growth of microorganisms that build up on surfaces and can form a biofilm. Cleaning of these surfaces within the machine is difficult and costly. With UVClean, JENSEN sought to innovate a simple solution to prevent the formation of biofilms.

Inspired by nature, perfected by JENSEN

The solution was both obvious and natural: UV-C rays are a natural and common approach for dealing with local biofilms. This method is also used in the pharmaceutical industry if treatment is to be carried out against multi-resistant microorganisms, for example antibiotics resistant bacteria. Microorganisms such as germs, viruses, or other pathogens are eliminated and/or their growth is prevented. Unlike other methods of disinfection, this does not require chemicals, so there is no problem regarding environmental compatibility and disposal. UV-C radiation is now used in an increasing number of areas, for example disinfection in sewage treatment plants, laboratories, air-conditioning systems, swimming pools, and aquariums, as well as in various phases of industrial processing of food and beverages. UV-C radiation is used in medical practices and hospitals to sterilize instruments, work surfaces, and ambient air.

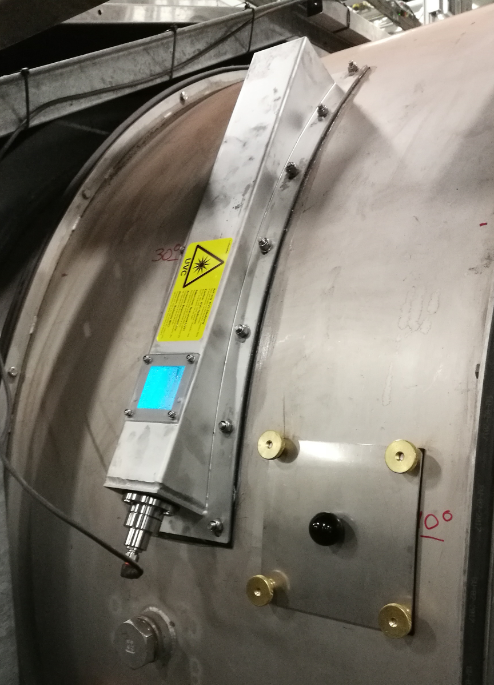

Two UV-C lamps are mounted in a housing on the outer drum in the tunnel washer. They radiate the internal surfaces between the inner and outer drum. Through reflection, the internal surfaces are reached and rid of microorganisms. This is a simple, virtually maintenance-free system with very low operating costs. The two 10 W bulbs have to be replaced after around one year. After 16 months of round-the-clock operation, the UV lamps still provide 75% of the radiation emission. Changing the lamps is very simple – as is cleaning the lamps. UVClean is also available as an option for retrofitting on existing JENSEN tunnel washers. Contact samples from the surfaces can easily be taken through two test flanges, making it possible to measure the efficiency of the UVClean system at any time. The light power of the lamps can also be tested through an inspection window.

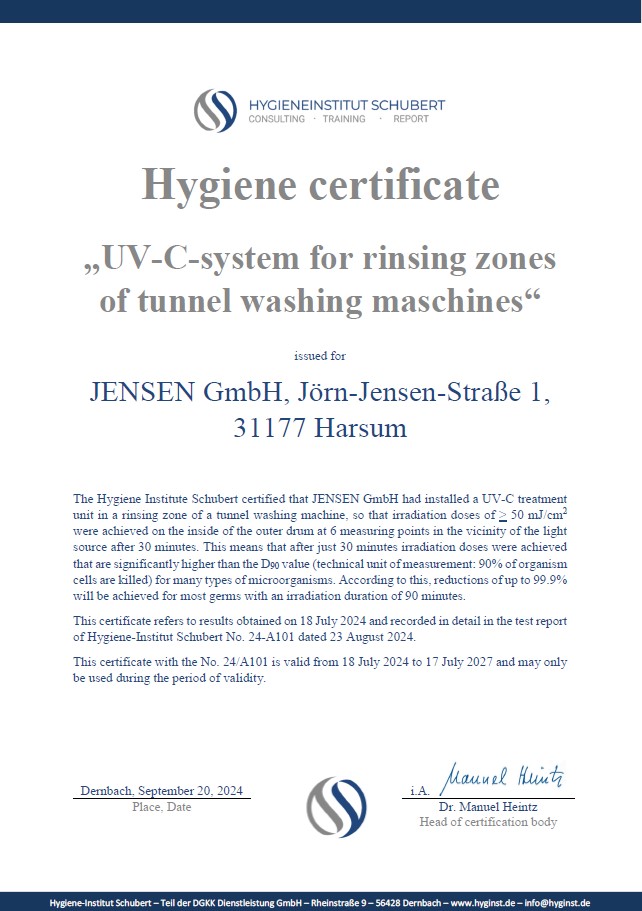

Tested, patented and certified

The JENSEN development team, together with the Hygiene-Institut Schubert based in Dernbach, Germany, carried out extensive tests in the customer’s laundry to verify the sterilization efficacy of UVClean. Hygiene-Institut Schubert installed UVClean in a rinsing zone of a tunnel washer so that radiation doses of > 50 mJ/cm² were reached after 30 minutes on the inside of the outer drum at multiple measuring points close to the light source. After just 30 minutes, radiation doses were significantly over the D90 value for many types of microorganism, meaning that with a radiation duration of 90 minutes, most germs were reduced by 99.9% percent.

"On the evaluated samples, we have reduced specific germs, as well as the total amount of germs. We were astonished by the results," states Martin Sukop, Sales Manager in the Washroom Technology Business Unit of JENSEN. "We are therefore able to highly recommend UVClean as an environmentally friendly and groundbreaking method for eliminating germs, and biofilms in tunnel washers. It is a simple, virtually maintenance-free system that safeguards laundries against various problems. And now we can even prove this with a certificate from the Hygiene-Institut Schubert, that's very important to us,“ reports a delighted Martin Sukop.

Officially certified: The effectiveness of UVClean has been confirmed by Hygiene-Institut Schubert.

The UV lamps are mounted on the outer drum.

Sunlight is essential for humans and nature. With UVClean, laundries can also benefit from this valuable resource.

UVClean, the new economical and environmentally friendly way to eliminate germs, bacteria, and biofilms in tunnel washers.