Clean, cleaner, UVClean: the new economical and ecological way to kill germs, bacteria and biofilms in the tunnel washer.

技術的記事

The new UVClean system (pat. pend.) in JENSEN tunnel washers prevents bacterial growth in double drum sections automatically and without any chemical supply – it is the most natural, most ecological and most efficient way of eliminating germs and bacteria. And what’s more: contrary to chemical methods, bacteria cannot become resistant to UV radiation. Once again, the JENSEN engineering team has come up with a simple, yet innovative way to add value to our customer’s laundries.

Bacterial contamination in a tunnel washer

Usually, all the linen is disinfected in the main washing zone of the tunnel washer. Nevertheless, there is a risk in all types of tunnel washers that the linen gets re-contaminated by microorganisms in the rinsing zone, namely because of bacterial biofilms within the tunnel washer that find a perfect breeding ground in a warm and humid environment in areas that are not consistently flushed by the wash liquor. The disinfection of internal surfaces in a tunnel washer is thus key to avoid germ growth and biofilms, and it’s a topic that many laundries are very well aware of. Below the bath level, the internal surfaces of the outer drum are constantly flushed with liquor. Thanks to the fluid mechanics, microorganisms cannot accumulate here, and disinfectants can act directly on the surfaces and prevent germ colonization. Above the bath level, the internal surfaces are not washed and are constantly kept moist by temperature, splash water such as liquor with detergents, auxiliary washing products, starch, as well as condensate. The conditions are warm and humid, similar to a steam bath. This climate favors the growth of microorganisms that accumulate on the surfaces and can form a biofilm. The cleaning of these surfaces on the inside of the machine is difficult and costly. Our target was to eliminate microorganisms on internal surfaces before any biofilm formation occurs.

Inspired by nature, perfected by JENSEN engineers

The solution was obvious and natural: Ultraviolet C radiation is a natural approach to current methods to treat localized biofilms. This method is also used in the pharmaceutical industry when multidrug-resistant microorganisms need to be cured, e.g. when antibiotics fail. It kills microorganisms such as germs, bacteria, viruses or other pathogens or prevent their growth. Compared to other disinfection procedures, it has the advantage that chemicals can be omitted and that these operations have no issues with emissions and disposal. UV-C radiation is now used for an ever increasing bandwidth of applications. For example, it is used for disinfection in purification plants, laboratories, air conditioning systems and even in swimming pools and aquariums as well as on various stages of the industrial processing of food and drinks. In medical practices and hospitals, the UV-C radiation is used to sterilize instruments, work surfaces and ambient air. In 2019, JENSEN is introducing UV-C technology for tunnel washer systems.

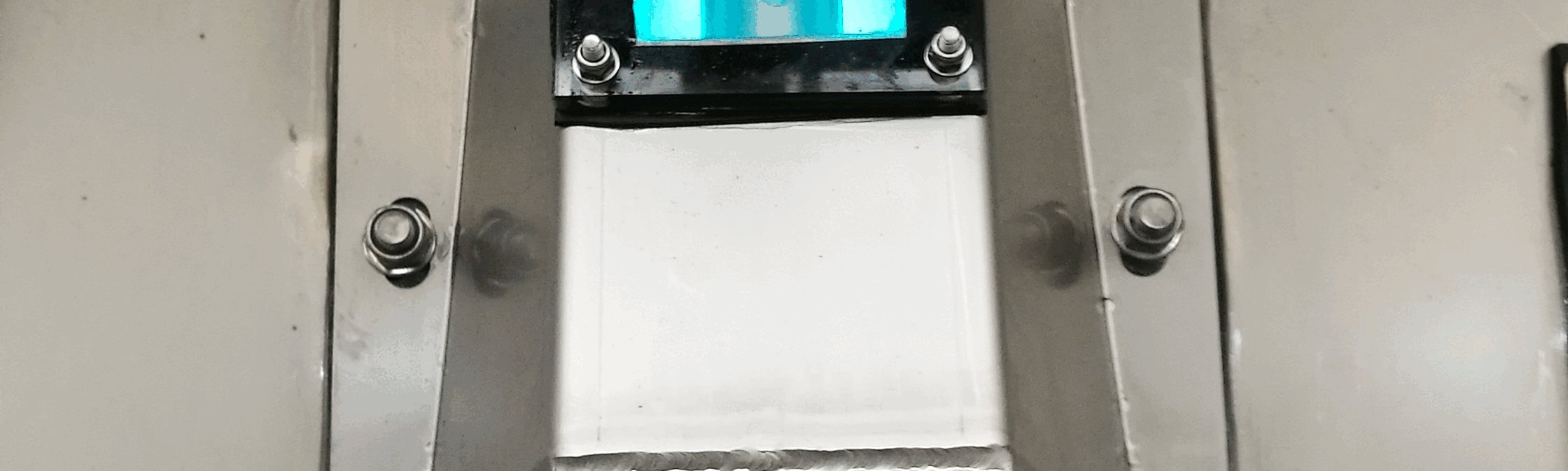

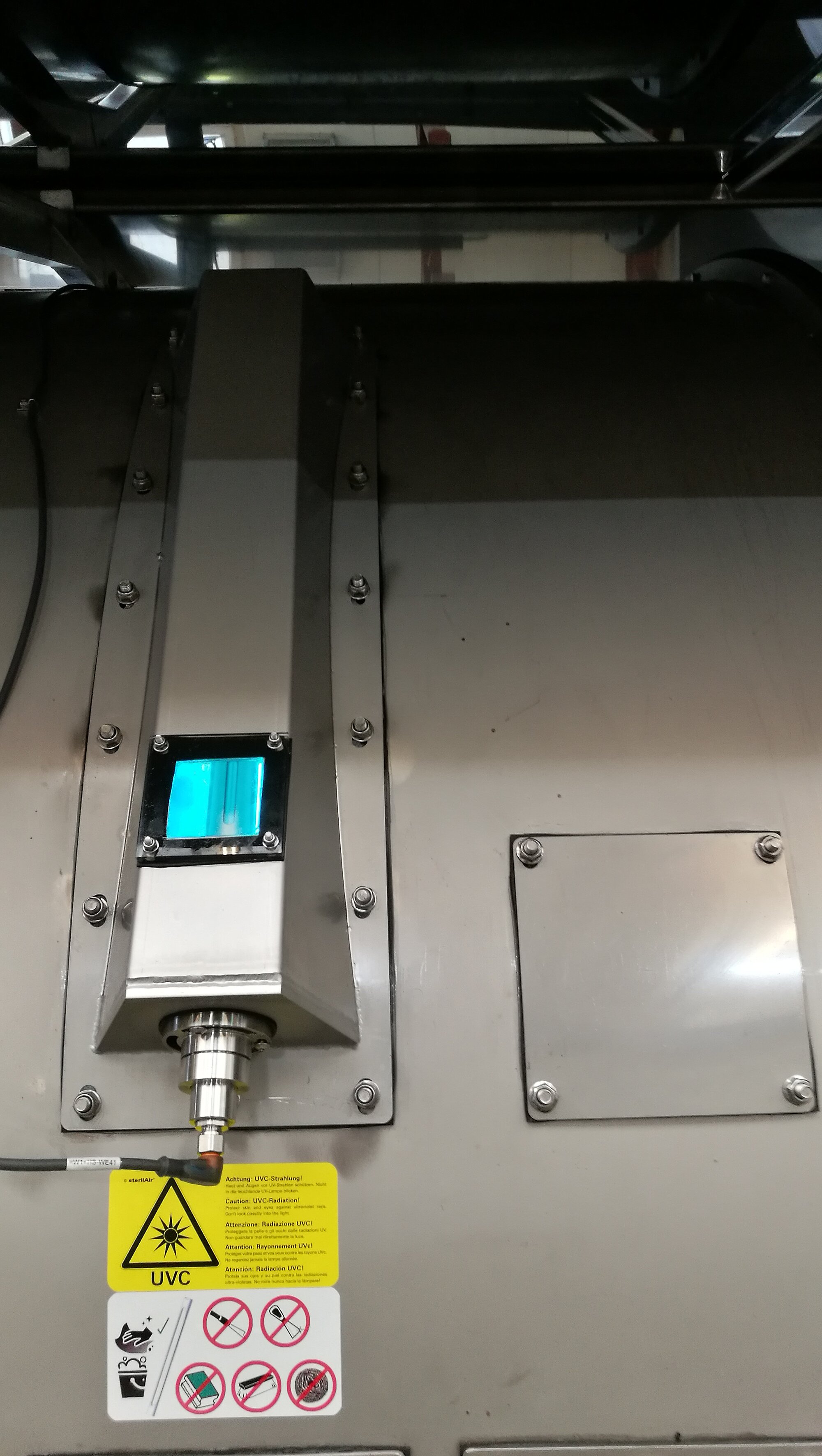

In the tunnel washer, two UV-C lamps mounted in a housing on the outer drum irradiate the inner surfaces between the inner and outer drums. The reflection effect reaches the inner surfaces and kills microorganisms. It’s a simple, almost maintenance-free system that can be operated at very low costs, with two 10W bulbs that need to be replaced approximately after one year. After 16 months with 24/7 operation, the UV lamps still produce 75% of the radiation emission. The exchange of the lamps is quite easy. Cleaning of the lamps is easy as well, and UV-Clean is also available as a retrofit option for existing JENSEN tunnel washers. Contact samples from the surfaces can easily be taken through two control flanges, meaning that the efficiency of the UVClean system can be measured at any given time. Also, the radiation performance of the lamps can be checked through inspection windows.

Test results

Extensive tests, carried out by the JENSEN development team at a customer’s laundry show the effectiveness of eliminating bacteria with UVClean. For this, the JENSEN development team used defined germinated DesValiG test specimens of the wfk Institute for Applied Research (wfk-iaf.de/en/). Via test flanges, the test specimens were inserted into the shell of an outer drum at different distances from the radiation source. The irradiation took place for a defined duration. The test specimens were then sent to the wfk Institute for evaluation.

«We evaluated the reduction of the defined sample germs as well as the total germ count, and were amazed by the results» says Martin Sukop, Manager Sales & Product Development for JENSEN’s Business Unit Washroom Technology. «That’s why we highly recommend UVClean as an ecological and viable way to eliminate germs, bacteria and biofilms in the tunnel washer. It’s a simple, almost maintenance free system that prevents laundries from a lot of problems.»

The two UV-C lamps and four sampling flanges. The function of the lamp can be observed through an inspection window on the lamp housing.

Even if some parts look clean: Contact samples give proof of contamination by biofilms.

The UV lamps are mounted on the outer drum.

Sunlight is vital for humans and for nature. With UVClean, also laundries can benefit from one of the most precious resources.