Triple-pass boiler

技術的記事

Feedback from a leading laundry group in Europe operating the Kalor G 1200 gas ironers reports record high performance with record low gas consumption compared to gas ironers of various brands used in a row of tests carried out by the laundry group during 2019. The test was carried out using heavy duvet covers as this type of flatwork contains a lot of residual moisture pushing the ironers to the limit.

Record speed of 45 meter (148 feet) per minute with duvet covers

Test results report a record high speed of 45 meter (148 feet) per minute with duvet covers containing 40% moisture. The result was reached operating a Kalor G 1200 gas ironer incorporating 3 rolls with a roll diameter of 1200 mm (48”) and a thermal oil boiler capacity of 750 kW. On top of that the ironer was supplied with the optional big gap pieces (two in total) increasing the ironing surface.

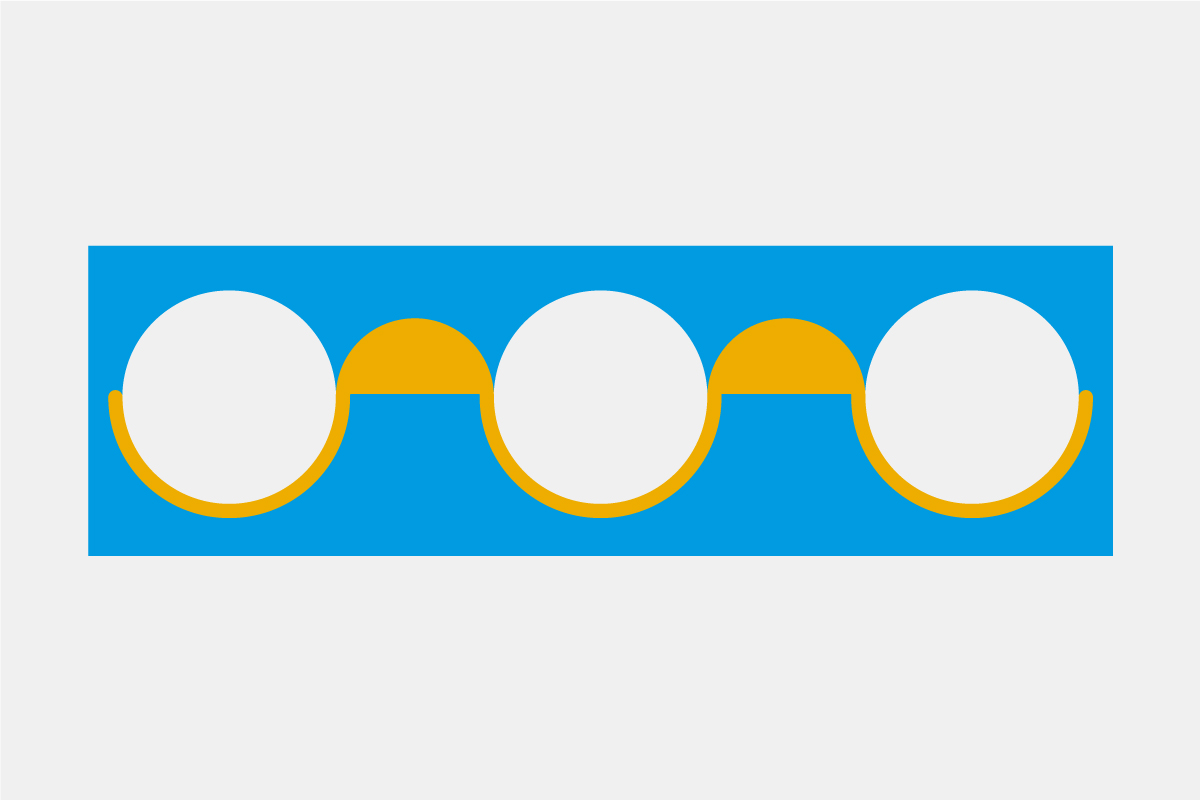

Additional chests by large diameter gap pieces

The new gap piece is direct heated and designed as a flexible chest turned “inside out and upside down”, adding another 1000 mm / 39” to the ironing length per gap piece. Both of the direct heated gap pieces of the 3 roll Kalor G 1200 ironer receive heated oil in a unique counter flow design ensuring that each gap piece can be heated to the maximum temperature. In principle each gap piece works as an extra roll of a smaller diameter, applying extra capacity to the ironer.

25% more volume

JENSEN has always used carbon steel material for ironing as this material gives a lower friction and a better heat conduction compared to stainless steel material. The new flexible chest combines the advantages of a fix chest and a flexible chest, incorporating bigger flow channels and thicker material. The thickness of the inner plate is almost doubled to 8 mm (0.315”) allowing to form bigger flow channels. Thanks to the new design, the oil volume inside the chest is increased by 25%, allowing to increase the evaporation capacity and reach new record speeds when ironing duvet covers.

Record low gas consumption

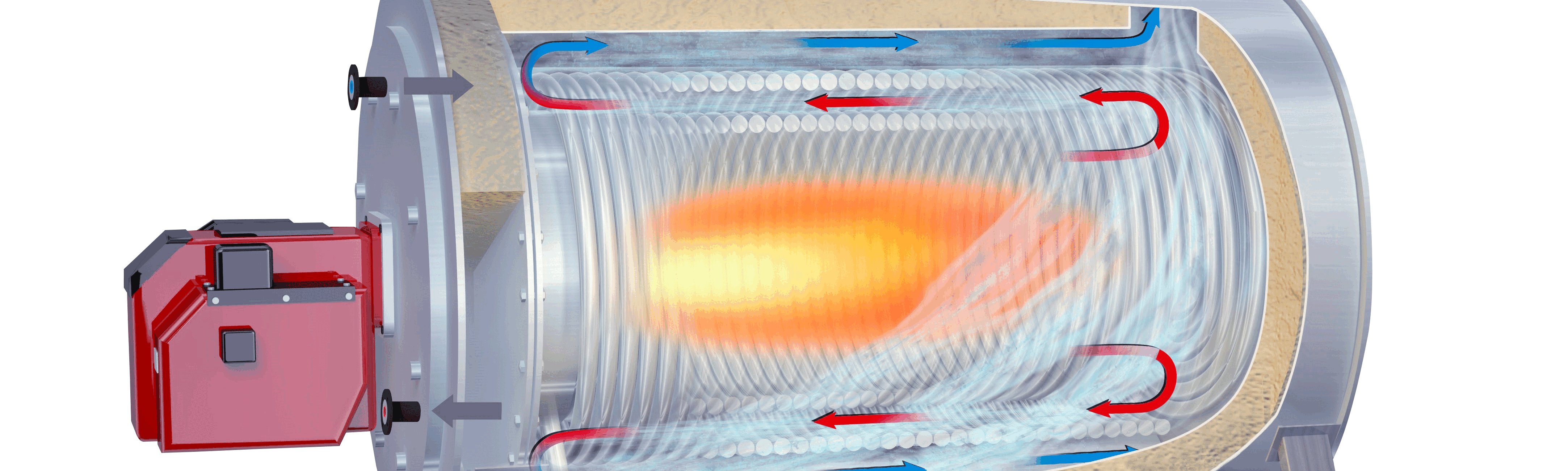

Thanks to a new triple pass boiler reducing the flue gas temperature to a minimum along with a PID controller with optimized process parameters, the energy efficiency reaches 90%. The PID controller regulates the modulating burner on the fly, and as a result, the Kalor G 1200 gas ironer reaches a record low energy consumption of only 1kWh per kilo (1,547 btu´s per lb) water evaporated. This is 10% lower compared to its predecessor – the EXPG 1200 gas ironer - and means that less energy is wasted, thus more energy is transferred into the flexible chest and used for evaporation of water.

15% increased capacity

Further advantages of the new boiler are, among others, a prolonged lifecycle of the burner and oil thanks to the PID controlled modulating burner. The PID control reduces the start/stop of the burner to a minimum, while at the same time a steady temperature close to the set point is maintained ensuring that the flatwork is equally dried across the entire surface.

Thanks to the sum of all the new features of the Kalor G 1200, the total capacity of the ironer is increased by 15% compared to its predecessor – the JENSEN EXPG 3x1200 gas ironer – allowing the new Kalor G 1200 gas ironer to be elected “Best-In-Class” by our customer.

Big gap piece

Principle sketch of big gap pieces

3-roll Kalor G 1200 gas ironer with big gap pieces