Combining the best of both worlds: The Kalor ironer combines the rigidity of a fixed chest ironer with the capacity of a flexible chest ironer.

专家网志

The Kalor ironer combines the durability and rigidity of a fixed chest ironer with the capacity of a flexible chest ironer. We call it a semi-flexible chest ironer; one of our customers calls it a workhorse that is also a racehorse.

The higher evaporation capacity of the semi-flexible chest offers two key benefits: Firstly, the extra evaporation capacity enables a higher output. Secondly, the ironing temperature can be reduced which extends the life of the linen without compromising the capacity.

The more, the better

What may not always be the wisest motto in daily life, it certainly is when looking at the inner workings of an ironer.

Whereas conventional flexible chest ironers contain chests with a thickness of 4 mm/0.157”, the Kalor ironers from JENSEN impress with a thick carbon steel plate of 8 mm/0.315”.

In the ironer, these eight millimeters/0.315” make a big difference.

The thicker chest made of carbon steel and its polished surface ensures a perfect contact to the roll and therefore fabulous finishing results. With this sustainable approach, laundries can extend the lifetime of the chest because deep scratches coming from e.g. steel buttons can easily be repaired.

This reminds us of a similar application in private homes: parquet flooring with original wood sustain for multiple decades and even generations as the wood can be ground off when wear and tear become visible. At first sight, laminate looks as good – but it requires full replacement after a couple of years.

As such, more material guarantees higher quality and longevity.

The outer plate of the chest has a thickness of 2 mm/0.08” with a new and unique welding pattern that provides more volume inside the flow channels. The oil volume inside the chest is increased by 25%, allowing to increase the evaporation capacity and reach record speeds. The parallel flow guarantees a higher and more stable heat distribution and surpasses chests with serial flow.

Carbon combats creases

JENSEN has always used carbon steel material for its ironers. Carbon steel outperforms stainless steel when it comes to finishing: the low friction of the wet linen reduces the risk of pleated linen, and at the same time, increases the lifetime of both linen and padding. It also requires less energy to drive the rolls and multiplies the heat conduction by a factor of four. The new flexible chest combines the advantages of a fixed chest and a flexible chest, incorporating bigger flow channels and thicker material.

A conventional fixed chest ironer cannot achieve the same evaporation capacity, which is further reduced as the padding wears over time, and as such, there is less contact to the roll.

Best in class

The new Kalor ironer has a higher evaporation capacity than any fixed chest ironer, and consumes minimal energy thanks to its new boiler and optional PID control. It’s best in class as confirmed by a leading laundry group in Europe, that achieves record high performance with record low gas consumption compared to gas ironers of various brands.

In any heavy-duty ironer, the more the better: a thicker chest, a higher evaporation, a better finishing quality, and a much better performance for more linen to be processed. These eight millimeters/0.315” will make a big difference in any laundry’s finishing section.

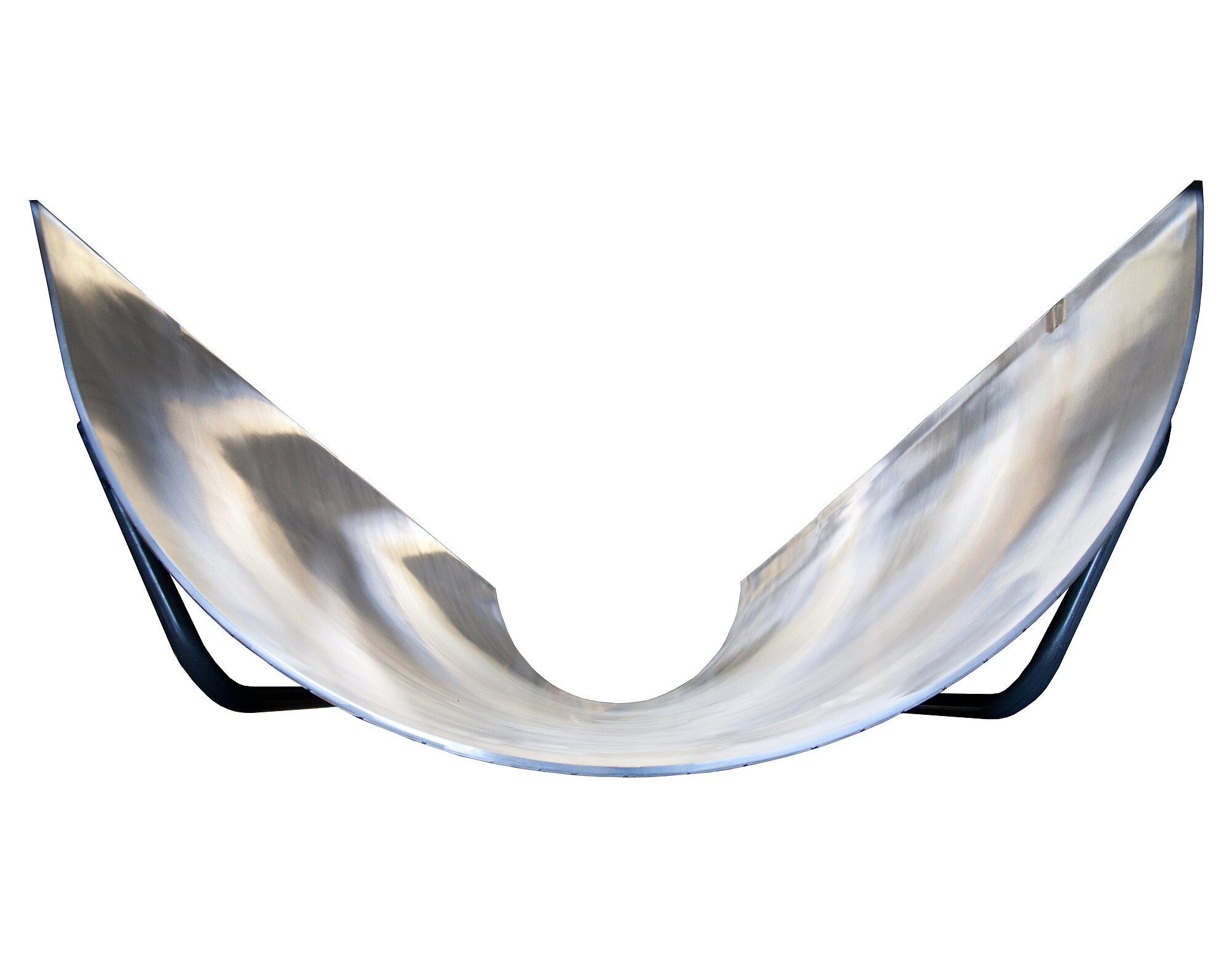

The new semi-flexible design of the chest

The thickness of the inner plate is almost doubled to 8 mm (0.315”) allowing to form bigger flow channels.

In Chinese culture, the figure “8” symbolizes success and prosperity. There are similarities to quality ironing, where the figure “8” in the chest also offers success and prosperity.