March to the Laundry!

News & Innovations

The laundry of the logistics base of the Swiss Army in Sursee (near Lucerne) processes more than 10 tons of wash and items for washing every day, which the Swiss army uses for its exercises. In total, more than 2,500 different items are washed at this facility and made ready for use again in the field. Socks and protective suits are washed just as thoroughly here as overshoes, tarpaulins and backpacks. Ammunition and other hazardous objects that should not find their way into the washing process must be removed before the thorough cleaning. It is a challenging mission for which there can be only one reliable partner.

No Sharp Shooting Here - Thanks to Odin

Ammunition, such as cartridge cases for rifles and pistons, the famous Swiss Army knife, padlocks and occasionally a lighter that was forgotten in a sleeping bag – all of these foreign objects do not belong in the washing process. An Odin X-ray scanner from Inwatec makes sure of that. This foreign object detection system is part of the “security brigade” here and uses artificial intelligence. Odin has to work very precisely, because it just takes one single forgotten cartridge and the entire ventilation system could blow, resulting in tremendously high costs. In the past, it has happened that a complete overhaul of the flatwork ironer was needed, because a padlock was hidden in a duvet cover. Camouflage applicators, which are feared for their stubborn spots, are also sorted out here.

After the initial safety check here, the wash is conveyed into a Futurail sorting facility, called the “bag train station” here in Sursee. Slightly more than 80 bags transport the wash in an optimal sequence to the 13 compartment tunnel washer.

In the field today, in the laundry tomorrow. And all of it....

There are likely very few laundries that wash shoes in their tunnel washer. This crazy idea is a reality in Sursee: The overshoes worn by the Swiss soldiers are washed in a new Senking Universal. Even tent tarps sized 1.6 x 1.6 m (5’ x 5’), each with 30 snap fasteners and various ropes, are processed in the tunnel washer. These so-called “Tarp 64” are used in the army as protective tents in exercises and in emergency operations. Thanks to the design of the Archimedean helix, the ropes and all other bulky objects are easily conveyed into the next compartment. Urs Mathis, head of the textile center, confirms that the Senking Universal is the only tunnel washing machine in the world that can process all of these specific items. “That was one of the most important requirements in the invitation of tenders,” says Urs Mathis:

“All items from the Swiss army that need to be washed can be washed here in the Sursee textile center.”

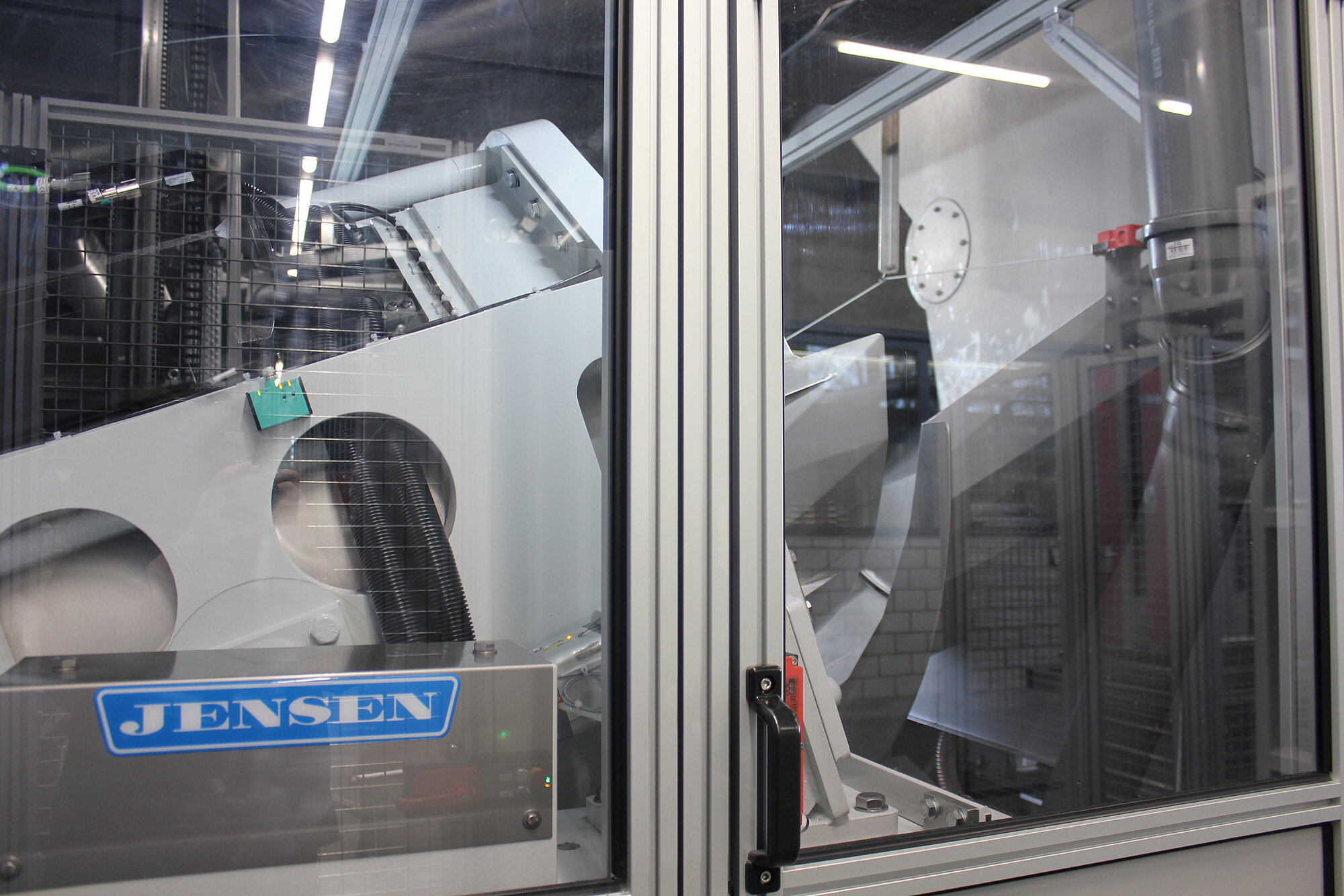

After extracting in the Z 1200 high-performance centrifuge, known for its drum with a high G-force of 800g’s, the bulk of the wash is conveyed to the dryers via conveyor belts. This is where the “green” heart of the laundry beats. The four new WR dryers are proven to be the most energy-efficient dryers in the world. The larger drum diameter and the optimized air flow reduce energy costs by up to 15% compared to conventional industrial dryers. After the drying process, the wash reaches the finishing area. The JENSEN system with a Variant feeder, a Jenroll flatwork ironer and a Universal folding machine have ensured a perfect finishing for many years.

Terry cloth towels and the so-called short goods, such as dish towels or cleaning cloths, quickly and easily reach the second dryer system with two additional WR dryers and the folding area by means of the VacuTrans vacuum transport system. “The ease of operation and the powerful telescopic nozzle convinced us immediately,” says Urs Mathis.

There are special drying chambers for drying the backpacks and tarpaulins. The drying process for impregnated items takes over four hours here. At 70 degrees C, the wax-based impregnation bonds with the fabric optimally so that the fabric is water-repellent again.

From the military to sports – a small step

The LBA (Logistics Base of the Army) with the two textile centers in Sursee and Thun washes the entire army’s laundry, including the laundry of all barracks and mobile hospitals of the Swiss Army – one of the few militia armies in the world with nearly 140,000 active soldiers and about 40,000 reservists. Their duties include defending the country, supporting civil authorities and promoting peace, as is currently the case in Kosovo and in Bosnia. The Swiss Army enjoys an excellent reputation among the Swiss population. Most employees at JENSEN AG in Burgdorf have also served in the army and are very proud of being able to continue to support the Swiss Army after their service.

The army is subordinate to the Swiss Federal Office of Defense, Civil Protection and Sports. The Sursee textile center therefore also processes the hotel laundry of the Swiss Federal Institute of Sport in Magglingen. Top athletes train here and prepare for international competitions. Very special items are sent from Magglingen to Sursee, such as life vests. And yes, the Senking Universal is also responsible for cleaning the life vests!

White cross on red background, and a green heart

The Swiss government adheres to strict rules when it comes to environmental protection. The prescribed CO2 savings also have to be achieved in the laundry facility. That is why the Federal Office for Defense Procurement (Armasuisse) has deliberately invested in the latest technology with the highest level of energy efficiency.

The new completely insulated tunnel washer requires less heating energy, since the heat loss is much lower than with the previous machine. Employees are also happy about this, because the room temperature is now up to 10 degrees Celsius lower and the noise level is several decibels quieter. Freshwater consumption is at a phenomenal 3.5 l/kg (.42 gal/lb) laundry throughout the entire washing process. Savings are also achieved when it comes to the washing chemicals: only five grams of detergent are used per kilogram (.088 oz/lb)of laundry. For comparison: Private household consumption uses about 20 g/kg (.35 oz/lb) of laundry. All the while items are always washed thoroughly: Anyone who has ever wanted to remove prints of camouflage paint on pillowcases knows that only high-performance machines can win the battle against stains!

In lockstep from 35 to 50

The new system was put into operation in September 2019. This new investment results in a tremendous increase in productivity in the washing room area. A cycle of laundry previously consisted of 35 kg (75 lbs.). Now it’s 50 kg (110 lbs.). In five working days, 16 employees and one specialist textile care trainee process about 50 tons of laundry.

The cooperation between the three in-house technicians and the customer service department has always been excellent, according to Urs Mathis. Even though only 49 km (30 mi) separate the JENSEN AG headquarters in Burgdorf and Sursee, the Federal Office for Defense Procurement insisted on a maintenance contract with defined intervention times. To ensure the availability of the equipment, a JENSEN technician can always be on site within 2.5 hours and technical questions are answered within an hour.

Urs Mathis praises JENSEN: The entire management is impressed by the new technology and the associated savings, and above all by the smooth installation phase.

“We had installation teams from the UK, Latvia, Denmark, Germany and of course Switzerland here in Sursee - everything went absolutely perfectly. It was a great experience for all of us.”

These boots are made for washing

The “Tarp 64” tent tarp pieces are used as protective tents in exercises and emergency operations. Thanks to the design of the Archimedean helix in JENSEN’s tunnel washer, the ropes and all other bulky objects are easily conveyed into the next compartment.

Foreign objects that do not belong in the washing process are detected by the Odin X-ray scanner utilizing artificial intelligence.

After the initial safety check here, the wash is conveyed into a Futurail sorting facility, called the “bag station” with 80 bags.

The Senking Universal P50 tunnel with 13 compartments is very versatile: All items from the Swiss Army that need to be processed can be washed in the tunnel washer.

800g: The Z 1200 high-performance centrifuge is known for its drum with a high G-Force

The new WR dryers are proven to be the most energy-efficient dryers in the world: The larger drum diameter and the optimized air flow reduce energy costs by up to 15% compared to conventional industrial dryers.

Backpacks and tarpaulins are dried in special drying chambers.

The Federal Office for Defense Procurement (Armasuisse) has deliberately invested in the latest technology with the highest level of energy efficiency: The new completely insulated tunnel washer requires less heating energy, since the heat loss is much lower than with the previous machine.

The flexible vacuum transport system VacuTrans boosts the productivity.

Stand-alone washer extractors JWE handle small batches of linen.

Meet the laundry team! From left to right: Hans Albisser, Head of the Laundry Organizational Unit; Janine Zaugg, Trainee; Christoph Gautschi, Deputy Head of the Laundry Organizational Unit; Urs Mathis, Head of the Textile Center